- Home

- >

News

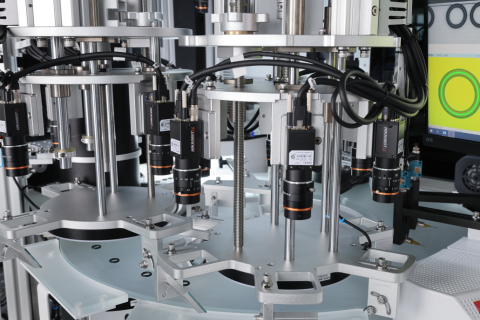

In today's demanding manufacturing landscape, ensuring the absolute precision and integrity of components like rivet caps is non-negotiable. Even minor defects – a minuscule scratch, a hair's breadth dimensional deviation, or a slight shape irregularity – can cascade into catastrophic product failures, costly recalls, and irreparable brand damage. The relentless pressure for perfection demands solutions beyond traditional manual inspection. Enter the Rivet Cap Optical Sorting Machine: an automated sentinel harnessing the power of light and artificial intelligence to safeguard quality at microscopic levels.

Unitecho’s fully automatic visual screening machines entail variable upfront costs depending on configurations. However, their long-term efficiency and precision often outweigh traditional manual methods, making them ideal for large-scale, high-accuracy manufacturing environments. By strategically selecting models and leveraging technological advancements, businesses can achieve significant cost savings while enhancing product quality.

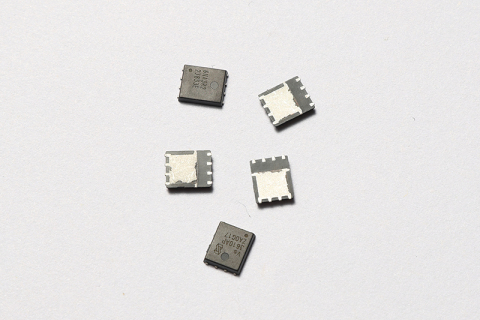

A combination of shims and screws is inspected using an Optical Sorting Machine, a sophisticated piece of equipment designed for high-speed image analysis. High-speed cameras capture clear images of both components, which are then transmitted to a computer system for meticulous processing.

The working principle of an external appearance inspection device relies on image analysis from industrial cameras. It customizes functional tests for various defects, such as polarity issues, misaligned edge seals, leakage, unbuckled edges, open seals, non-circular seals, bulges greater than 0.2mm, faulty caps, incorrect specifications, bad soldering points, color inconsistencies, and missing pins. Size detection involves checking dimensions like length, width, height, thread diameter, and specific local requirements.

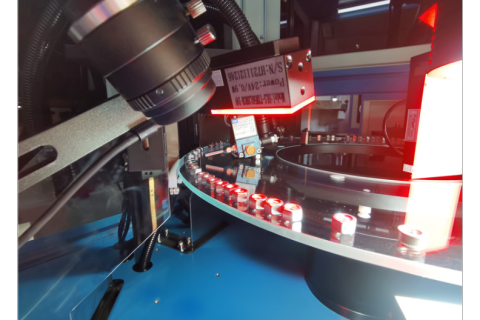

As the product moves beneath the CCD sensor, the indexing platform halts, triggering a signal for the CCD to capture an image for comparison. The CCD processes the data, determining whether the product meets the quality criteria. If the product passes, the CCD sends another signal to the indexing platform, allowing it to proceed to the next work station for another image analysis. This continuous cycle repeats until all items are inspected, and they are then discharged into a frame.