- Home

- >

- News

- >

- company news

- >

News

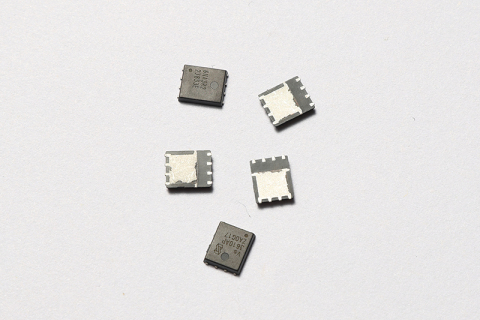

In the relentless pursuit of manufacturing perfection, a single micron-scale scratch on a semiconductor wafer or a hairline crack in a battery cell can trigger catastrophic failures. Traditional human inspection, limited by physiological constraints and subjective judgment, struggles to keep pace with today’s nano-scale production tolerances. This is where AI-driven vision inspection systems emerge as the ultimate quality guardian – merging optical precision with algorithmic intelligence to achieve what was once deemed impossible.

In today’s high-speed manufacturing environments, detecting sub-millimeter defects on moving production lines demands superhuman capabilities. Traditional rule-based vision systems buckle under variations in lighting, texture, and object orientation. This is where the fusion of deep learning (DL) and optical sensing creates a paradigm shift. Here’s how AI-driven visual inspection and optical sorters achieve unprecedented accuracy and adaptability.

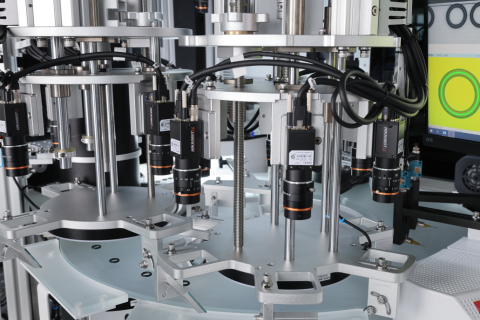

The relentless drive towards miniaturization and hyper-connectivity places immense pressure on connector manufacturers. In this high-stakes arena, where a single micron-scale defect can lead to catastrophic system failures, the connector optical sorter has emerged as the indispensable guardian of precision and quality. This sophisticated machine is not just a quality control tool; it’s the bedrock of reliability for countless electronic devices powering our world.

In today's demanding manufacturing landscape, ensuring the absolute precision and integrity of components like rivet caps is non-negotiable. Even minor defects – a minuscule scratch, a hair's breadth dimensional deviation, or a slight shape irregularity – can cascade into catastrophic product failures, costly recalls, and irreparable brand damage. The relentless pressure for perfection demands solutions beyond traditional manual inspection. Enter the Rivet Cap Optical Sorting Machine: an automated sentinel harnessing the power of light and artificial intelligence to safeguard quality at microscopic levels.

Unitecho has achieved a major breakthrough in optical sorting technology, securing two national patents. According to the China National Intellectual Property Administration, the patents include the "Multi-Functional Optical Sorting Workstation" (Authorization No. CN222402392U) and the "Optical Image Sorting Machine with Automatic Material Centering Structure" (Authorization No. CN222402365U), filed in April and May 2024, respectively.

In an era of precision and innovation, the optical sorting machine stands as a beacon of technological advancement. Harnessing the power of cutting-edge optics, these machines redefine the standards of accuracy and productivity in various industries. The art of design meets science as these devices seamlessly integrate sophisticated algorithms with sleek and compact designs.

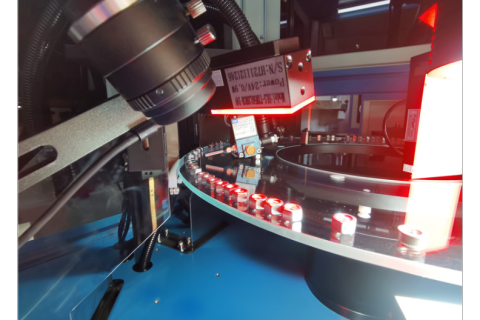

The working principle of an external appearance inspection device relies on image analysis from industrial cameras. It customizes functional tests for various defects, such as polarity issues, misaligned edge seals, leakage, unbuckled edges, open seals, non-circular seals, bulges greater than 0.2mm, faulty caps, incorrect specifications, bad soldering points, color inconsistencies, and missing pins. Size detection involves checking dimensions like length, width, height, thread diameter, and specific local requirements.

As the product moves beneath the CCD sensor, the indexing platform halts, triggering a signal for the CCD to capture an image for comparison. The CCD processes the data, determining whether the product meets the quality criteria. If the product passes, the CCD sends another signal to the indexing platform, allowing it to proceed to the next work station for another image analysis. This continuous cycle repeats until all items are inspected, and they are then discharged into a frame.