- Home

- >

News

In the relentless pursuit of manufacturing perfection, a single micron-scale scratch on a semiconductor wafer or a hairline crack in a battery cell can trigger catastrophic failures. Traditional human inspection, limited by physiological constraints and subjective judgment, struggles to keep pace with today’s nano-scale production tolerances. This is where AI-driven vision inspection systems emerge as the ultimate quality guardian – merging optical precision with algorithmic intelligence to achieve what was once deemed impossible.

The relentless drive towards miniaturization and hyper-connectivity places immense pressure on connector manufacturers. In this high-stakes arena, where a single micron-scale defect can lead to catastrophic system failures, the connector optical sorter has emerged as the indispensable guardian of precision and quality. This sophisticated machine is not just a quality control tool; it’s the bedrock of reliability for countless electronic devices powering our world.

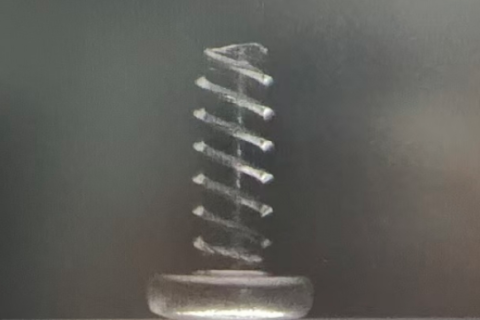

In the intricate world of precision fastening, the humble washer-fastener assembly (a screw combined with a pre-assembled washer) plays a crucial role. Whether ensuring proper load distribution, preventing loosening, or acting as a seal, the integrity of this bonded pair is paramount.

In the realm of precision engineering, screws and nuts play a pivotal role. However, despite their importance, manufacturing imperfections can sometimes affect their visual appearance. Here's an overview of some common defects that may be observed: