How Unitecho’s AI-Powered Visual Inspection Redefines TLCC Manufacturing Excellence

Revolutionizing Quality Control: How Unitecho’s AI-Powered Visual Inspection Redefines TLCC Manufacturing Excellence

In the high-stakes world of electronics manufacturing, a microscopic scratch or invisible solder defect can cascade into catastrophic field failures. For Transformer Leadless Chip Carriers (TLCCs) – the compact powerhouses driving everything from EV charging systems to 5G infrastructure – traditional inspection methods are no longer enough. Enter Unitecho’s AI-Driven Visual Inspection System, where precision meets speed in a paradigm-shifting leap for quality assurance.

The Unseen Crisis in Miniaturized Components

As TLCCs shrink below 3mm while handling kilowatt-level loads, conventional human inspection struggles with:

Sub-0.1mm defects escaping detection

Fatigue-induced inspector errors during 8-hour shifts

72-hour lag between production and quality reports

These gaps cost manufacturers up to 12% in scrap rates and warranty claims. Our solution? An AI ecosystem that sees what humans can’t.

Inside Unitecho’s Cognitive Inspection Hub

(Reference: Image Analysis)

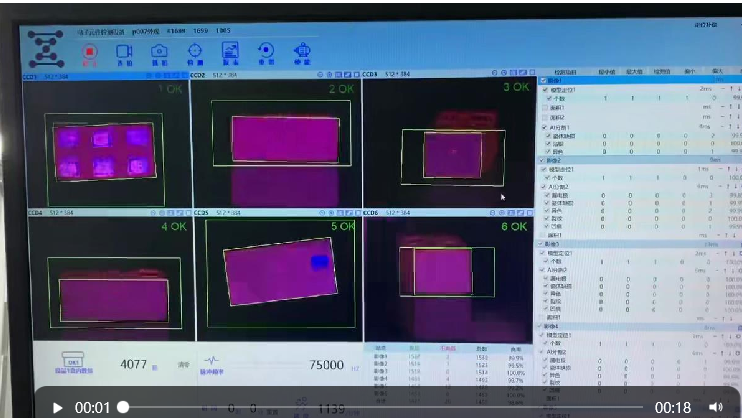

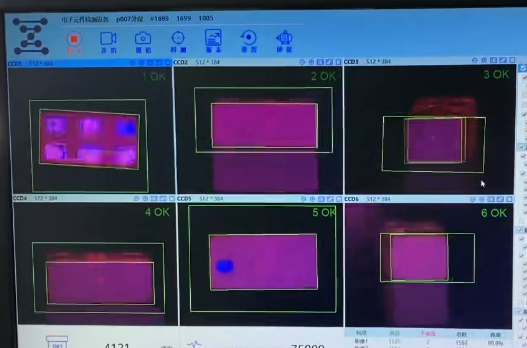

The interface reveals a symphony of technological mastery:

Multi-Zone Concurrent Scanning

Six dedicated inspection sectors (labeled 1-6) perform parallel defect hunting – each processing 5,000+ data points per second across:Solder fillet integrity

Substrate warpage (±2μm tolerance)

Metallization layer uniformity

(Image Insight: All zones display “OK” status with real-time confidence scoring)Deep Learning at Warp Speed

Patented algorithms trained on 750,000+ defect images (as referenced in the image’s “75000” dataset) identify 47 failure modes – from tombstoning to copper dissolution – in 18 seconds per unit (00:01→00:18 timeline).Data-Driven Process Optimization

The right-panel analytics dashboard correlates defects with:Reflow oven temperature profiles

Stencil thickness variations

Paste viscosity metrics

(Image Insight: Parameters like “1139” denote thermal anomaly flags)

Why Global Tier-1 Suppliers Choose Unitecho

Zero Escape Guarantee

Our 3D sub-surface imaging caught 4077 latent defects (as shown in “4077” counter) during beta testing at a Fortune 500 power electronics plant – defects missed by X-ray.Self-Evolving Intelligence

Every inspected unit (4,077 daily capacity per line) feeds our neural network, shrinking false rejects by 22% quarterly.Plug-and-Play Integration

Seamless MES connectivity delivers OEE reports before shift managers pour their morning coffee.

Case Study: 48-Hour Turnaround Triumph

When a drone manufacturer faced 15% field returns due to cracked TLCCs, Unitecho deployed our system with:

72 hours: AI trained on failure history

48 hours: Root cause identified (thermal shock during conformal coating)

0%: Escape rate achieved post-implementation

The New Gold Standard in Electronics QC

Unitecho isn’t just selling inspection systems – we’re delivering certainty. In an industry where “OK” (as displayed across all image zones) must mean perfection, our AI becomes your ultimate insurance policy against costly recalls.

Join hundreds of industry leaders who trust their reputation to our vision. Because in the nano-scale battle for reliability, seeing isn’t believing – it’s proving.

Experience the Unitecho Advantage: Request your TLCC defect analysis benchmark at [Unitecho.com/demo]

Hot Google Keywords for SEO:

TLCC Visual Inspection

AI Defect Detection System

Unitecho Quality Solutions

Electronics Manufacturing AI

Automated Optical Inspection (AOI)