Steel Belt Type Optical Sorting Machine

The UTH-500 Steel Belt Type Optical Sorting Machine is a state-of-the-art solution designed for the precise inspection of spring components. With its high-resolution detection system, it efficiently identifies defects such as deformation, broken wires, and weld points, ensuring quality control for various spring types including compression and tension springs.

✅ High-Resolution Detection for Accurate Defect Identification

✅ Efficient Inspection of Compression and Tension Springs

✅ User-Friendly Interface for Easy Operation and Setup

Software Advantages

Advanced Optical Inspection System

The UTH-500 features a sophisticated optical system that provides detailed imaging of spring components, enabling the detection of minute defects that could affect performance.

High-Speed and Precision Sorting

Equipped with a steel belt conveyor, this machine ensures high-speed and precise sorting, reducing inspection times without compromising accuracy.

Intelligent Data Management

The integrated data management system of the UTH-500 automatically logs all inspection data, providing comprehensive reports for quality assurance and process improvement.

Rapid Changeover Capabilities

The machine is designed for quick changeovers between different spring types, minimizing downtime and enhancing production flexibility.

Adaptable to Various Spring Types

The UTH-500 is versatile, capable of inspecting a wide range of spring components, making it suitable for diverse manufacturing needs.

Usage Scenarios

Automotive Rubber and Sealing Components

For automotive rubber and sealing components that incorporate springs, the machine provides thorough inspection to maintain sealing integrity and prevent leaks.

Automotive Precision Machined Parts

The UTH-500 is ideal for inspecting precision-carved spring components used in automotive applications, ensuring reliability and performance in critical vehicle systems.

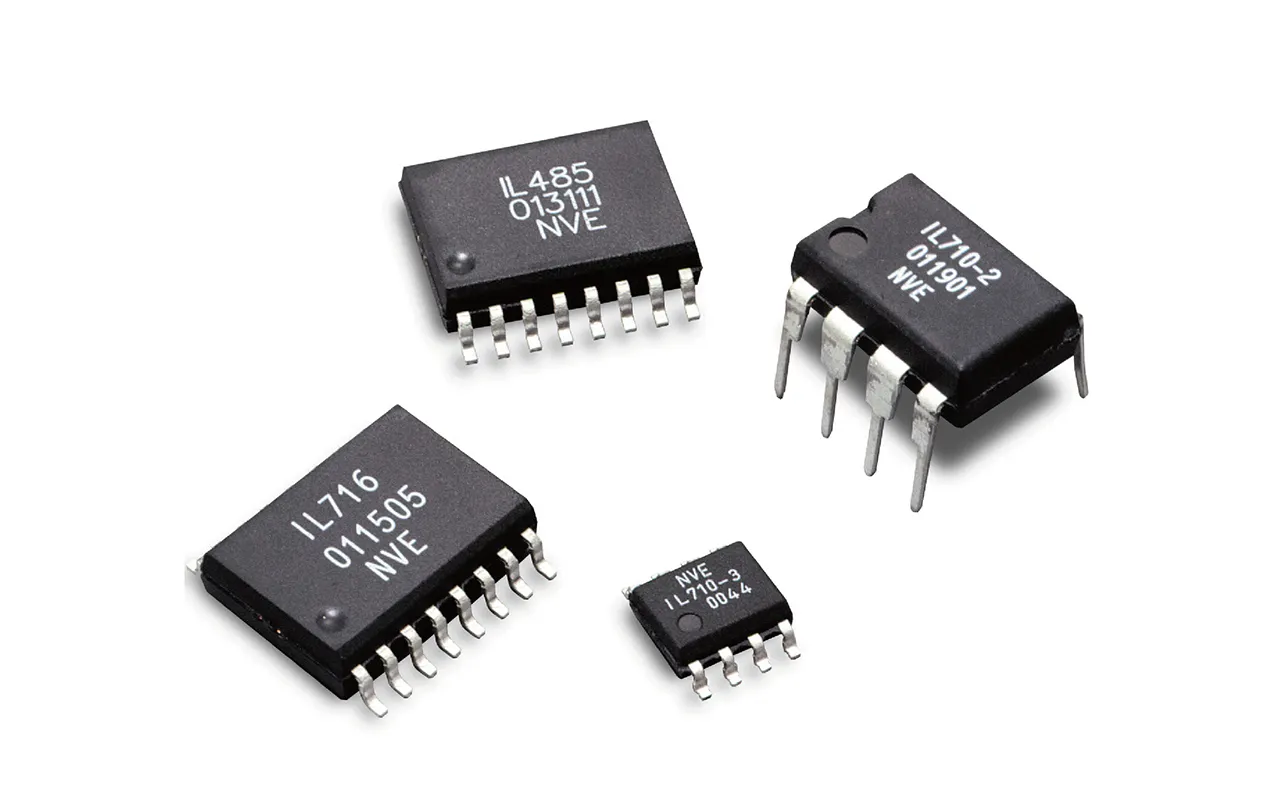

Electronics Structural Components

For structural components in consumer electronics that rely on spring mechanisms, the machine ensures precise inspection to maintain product quality and functionality.

Electronics Micro-precision Parts

In the electronics industry, the UTH-500 inspects micro springs used in devices like smartphones and earbuds, ensuring they meet high standards for durability and performance.

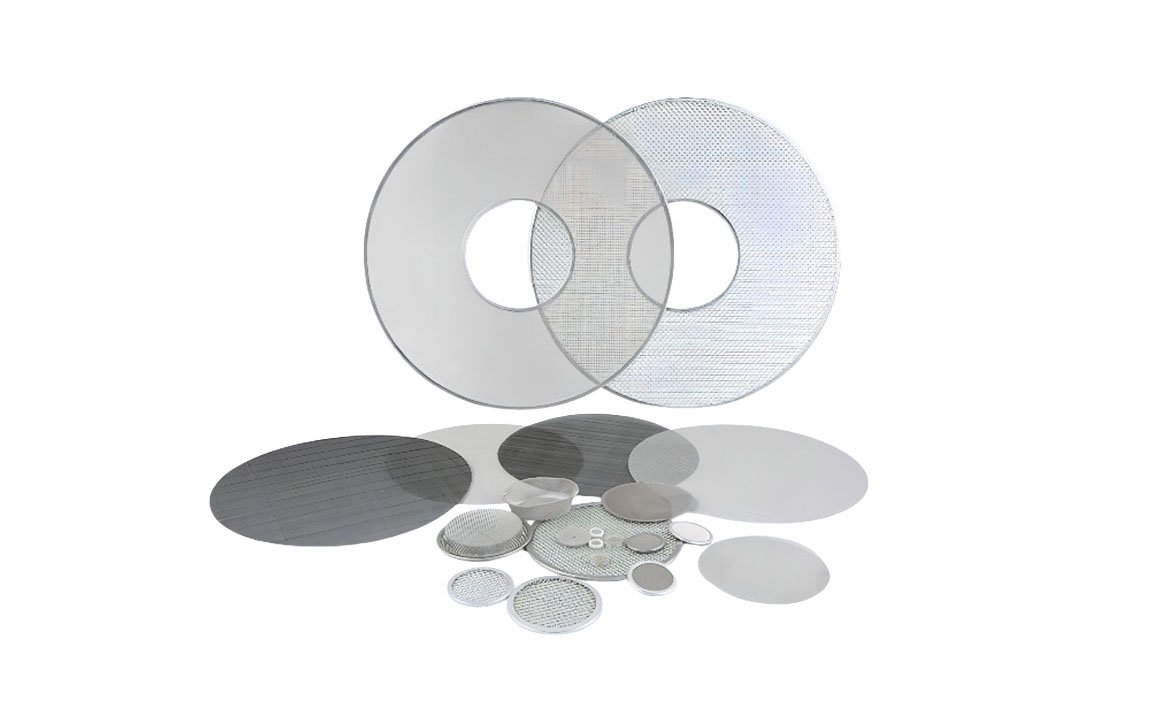

Semiconductor Passive Components

In the semiconductor industry, the UTH-500 inspects passive components that incorporate springs, ensuring they meet the high precision required for electronic applications.

Semiconductor Interconnects

For connection components in semiconductors, the machine ensures the springs are defect-free, crucial for maintaining the integrity of electronic connections.

Medical Injection Molding Consumables

For injection-molded medical consumables that include spring components, the machine provides detailed inspection to maintain compliance with medical standards.

Medical Electronic Components

The UTH-500 can inspect springs used in medical electronic devices, ensuring they meet stringent quality requirements for safety and reliability.

Product Parameters

| Item | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

|---|---|---|---|---|

| Model | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

| Detection disc diameter | 500mm | 600mm | 800mm | 1000mm |

| Equipment size | 928*1000*1900 | 1060*1060*1900 | 1280*1280*1980 | 1280*1480*1980 |

| Equipment weight | 750KG | 800KG | 900KG | 1000KG |

| Voltage | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) |

| Frequency | 50HZ/60HZ | |||

| Power | 3KW | 4KW | ||

| Air pressure | 0.5-0.8Mpa | |||

| Applicable workpiece | Utilizing the high light transmittance of glass, workpieces that can be placed stably on the glass plate can be inspected. | |||

| Feeding method | Belt and rail conveyors | |||

| Feeding direction | clockwise/counterclockwise | |||

| Inspection items | Dimensional and appearance defects, such as diagonal edges, head size, stem, inner hole, pits, cracks, tooth damage, etc. | |||

| Maximum number of cameras | 4 Pcs | 8 Pcs | 12 Pcs | 16 Pcs |

| Speed | ±800Pcs/min | ±600Pcs/min | ±500Pcs/min | |

| Accuracy | ≥±0.002mm | |||

| Accessories can be added | It can be equipped with vertical feeding machines, climbing machines, storage bins, etc., and can be connected to packaging and baling machines. | |||

| Computer | Standard I7 industrial-grade computer (AI algorithm equipped with NVIDIA high computing power graphics card) | |||

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + AI algorithm platform UIDI + AI defect generation software UIDG. | |||

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province