Software Advantages

Measure over 100 dimensions in 1 second

In the past, more measurement positions meant longer measurement time.However, IVT-VISION can measure over 100 dimensions simultaneously,and complete the measurement in just 1 second.It can greatly reduce the time required for measurement.

Easy operation for anyone

The user interface is simple and easy to understand. Just click the buttons on the screen,and anyone can get stable measurement results.In addition, the operation steps are visible on the screen, so anyone can set it up easily.

Unified management of measurement data

Measurement data is automatically saved upon completion of measurement, facilitating unified storage and management of data.A test result report can be generated with just one click of a button.Post-measurement tasks can also be made more efficient.

No need to position the measurement object or origin

It remembers the shape of the measurement object, automatically detects the position and orientation of the object placed on the measurement coordinate table, and then performs the measurement. No positioning or fixing fixtures are required.

No deviation caused by focus adjustment

It is equipped with an optical lens specially designed for large depth of field. In addition, it has an auto-focus function. For measurement objects that cannot be focused at once due to uneven surfaces,it can auto-focus according to the measurement position, thus eliminating focus errors caused by different operators.

Usage Scenarios

Automotive Stamping Parts

The OMQ series is the perfect solution for verifying hole position deviations and profile contours on flat metal parts, ensuring precise fit and structural integrity in body and chassis components.

Automotive Rubber & Sealing Components

Its non-contact measurement capability prevents deformation when inspecting soft gaskets and seals, accurately identifying dimensional instability and verifying inner and outer diameters.

Automotive Plastic Parts & Structural Components

The system reliably detects warpage and verifies critical assembly dimensions on complex interior and exterior plastic parts.

Automotive Fasteners

It delivers rapid checks of head diameters, washer thickness, and thread profiles for fasteners placed flat on the stage.

Electronics Structural Components

Leveraging Instant One-Key Measuring technology, the system verifies complex geometric tolerances—including flatness, hole positions, and profile contours—on smartphone mid-frames and SIM trays for slim, high-density devices.

Electronics Metal Hardware

It precisely measures dimensional deviations in shielding cans and small flat hardware to ensure strict adherence to functional standards.

Plastic Components

It precisely measures dimensional deviations in shielding cans and small flat hardware to ensure strict adherence to functional standards.

Semiconductor Wafers & Support Components

Featuring advanced image stitching capabilities, the OMQ series captures the complex contours of large lead frames and wafers, ensuring the precise alignment and dimensional integrity of foundational layers.

Semiconductor Interconnects

It strictly measures critical parameters such as pin coplanarity (Z-axis) and pitch alignment to effectively prevent connectivity failures.

Medical Injection Molding Consumables

The system rapidly measures rubber stoppers and O-rings for dimensional accuracy without physical contact, maintaining the hygiene and shape of sterile consumables.

Medical Fasteners

It verifies the complex geometry of bone plates and the head profiles of surgical screws to meet rigorous medical manufacturing tolerances.

Medical Electronic Components

It provides high-precision inspection of dimensions for miniature sensors and MLCCs, ensuring consistency in sophisticated medical devices.

Military Precision Fasteners

The machine verifies Mil-Spec tolerances on aviation screws, specifically checking head dimensions and lengths to ensure absolute airworthiness.

Military Optoelectronic Components

It performs non-contact dimensional inspection on sensitive lenses and filters, preserving flawless optical performance without risk of damage.

Military Precision Fasteners

The system guarantees the structural consistency and dimensional accuracy of tungsten and ceramic parts designed for extreme thermal and kinetic environments.

Product Parameters

| General technical parameters of equipment | |

|---|---|

| Parameter | Specification |

| Model number | UIDI V600 |

| Equipment (size: L x W x H) | 1000mm×1000mm×1900mm |

| Overall weight | 400kg |

| Communication | Network (supports OPC, WebAPI, TCP/IP, SQL Server, etc.) |

| Voltage | 220V/50Hz |

| Atmospheric pressure | 0.5-0.8MPa |

| General technical parameters of equipment | |

| Parameter | Specification |

| Detecting element | MLCC |

| Detection size | British: 0201, 0402, 0603, 0805, 1206, 1210, 1812, etc. |

| Detection item | Electrode size, body size, scratches, cracks, pollution defects, discoloration, dark cracks, etc. |

| Test term | Electrode size, body size, scratches, cracks, pollution defects, discoloration, dark cracks, etc. |

| Software system | UIDI AI system, NAS platform |

| Resolution | 2.3 μm pixels/5.45 μm pixels/4.6 μm pixels/6.9 μm pixels |

| CCD camera | USB3.0, GigE |

| Lens module | High-resolution lens |

| Light | High-brightness multi-angle light source |

| Illuminant | High-brightness multi-angle light source |

| Feeding mechanism | High-speed imported vibrating plate, with special surface treatment to effectively avoid scratches during long-term production |

| Feeding guide mechanism | High-precision guide device, with electrostatic protection device |

| Optical glass disc | 300mm diameter, flatness ≤0.005mm, thickness: 10mm, parallelism ≤0.001mm (10 points) |

| DD rotating platform | High-precision DD motor (20bit) |

| DD rotating platform | High-precision DD motor (20bit) |

| High speed solenoid valve | Long service life (500 million times, maintenance-free), high frequency (1200Hz) |

| Discharge opening | 4-6 receiving boxes (configurable according to customer demand) |

| Discharge | 4-6 receiving boxes (configurable according to customer demand) |

| Passive element detection speed |

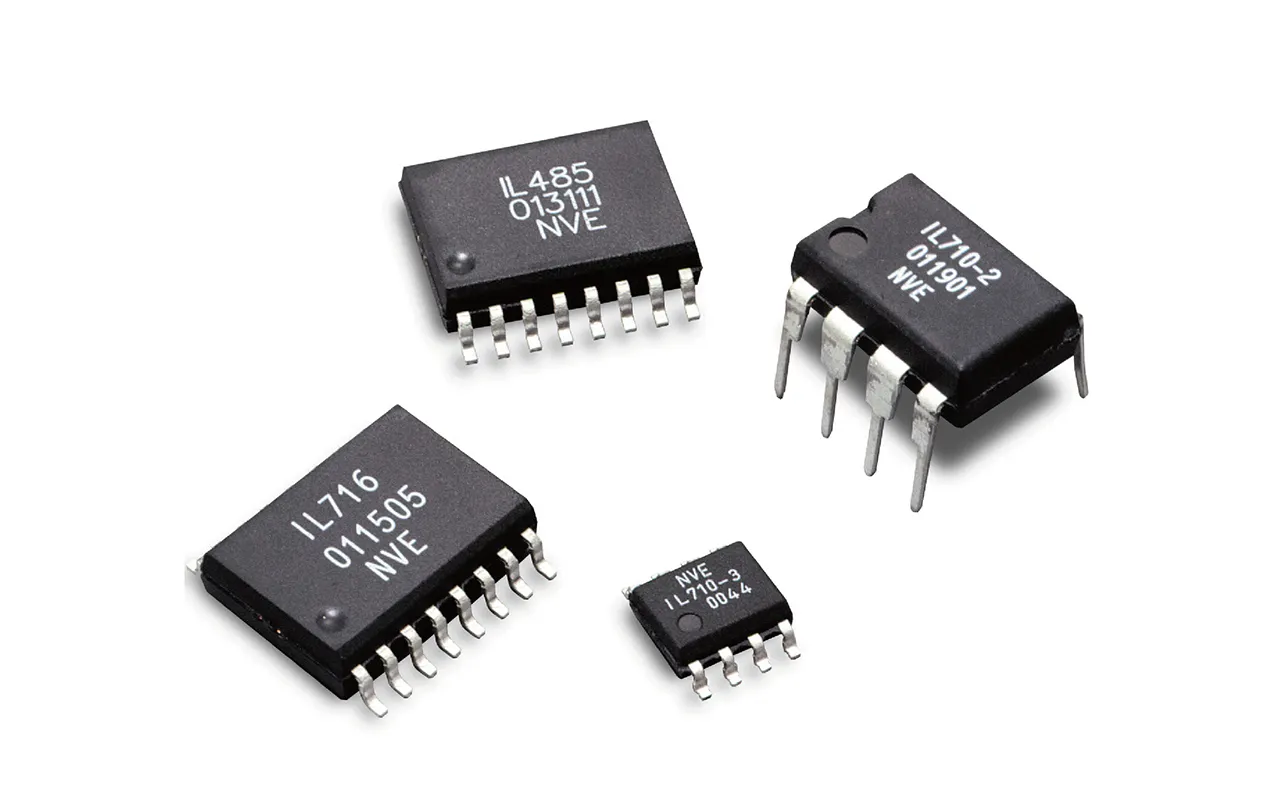

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province