UGV-FR-VI Glass Turntable Metal Parts Optical Sorting Machine

High-Capacity 12-Camera Visual Inspection System

The UGV-FR-VI is a robust, large-format optical sorting machine designed for the comprehensive inspection of medium-to-large flat components. Featuring an expanded 800mm high-transmittance glass detection disc, this system supports a powerful configuration of up to 12 industrial cameras. This extensive multi-view capability allows for simultaneous top, bottom, side, and angled inspections, eliminating blind spots on complex workpieces. With a measurement accuracy of ±0.002mm and a sorting speed of ≤500 pcs/min, the UGV-FR-VI delivers uncompromising quality control for automotive stampings, electronic hardware, and precision fasteners.

✅ 800mm Large-Format Glass Platform for Increased Versatility

✅ 12-Camera Matrix for 360° Blind-Spot-Free Inspection

✅ Ultra-High Precision: ±0.002mm Repeatability

✅ AI-Core: UZVISION Platform with Deep Learning Defect Detection

Software Advantages

12-Camera Multi-Angle Inspection

This system supports up to 12 cameras, enabling multi-angle coverage to inspect complex parts like stepped nuts. It reliably detects defects such as thread damage and side cracks that are often missed by single-view systems.

Large Glass Turntable & Stable Structure

Equipped with an 800mm glass turntable and weighing 900kg with a 4KW drive, the machine offers superior stability for smooth handling of larger workpieces. This robust design ensures consistent ±0.002mm accuracy during high-speed operation.

High Precision & High-Speed Detection

It achieves a detection accuracy of ±0.002mm at speeds up to approximately 500 pieces per minute. The system inspects various dimensional and appearance defects, including edges, head size, inner holes, pits, and cracks.

AI-Powered Vision Platform

The system runs on an NVIDIA GPU and UNITECHO's proprietary software suite: UZVISION, UIDI, and the AI defect generation tool UIDG. This allows rapid synthetic defect sample creation and model training, significantly reducing deployment time for new applications.

Modular Design & Automated Integration

It supports flexible feeding via belt or rail conveyors and integrates seamlessly with peripheral equipment like loaders and storage bins. This enables a fully automated "inspect-to-package" workflow by connecting directly with downstream packaging systems.

Usage Scenarios

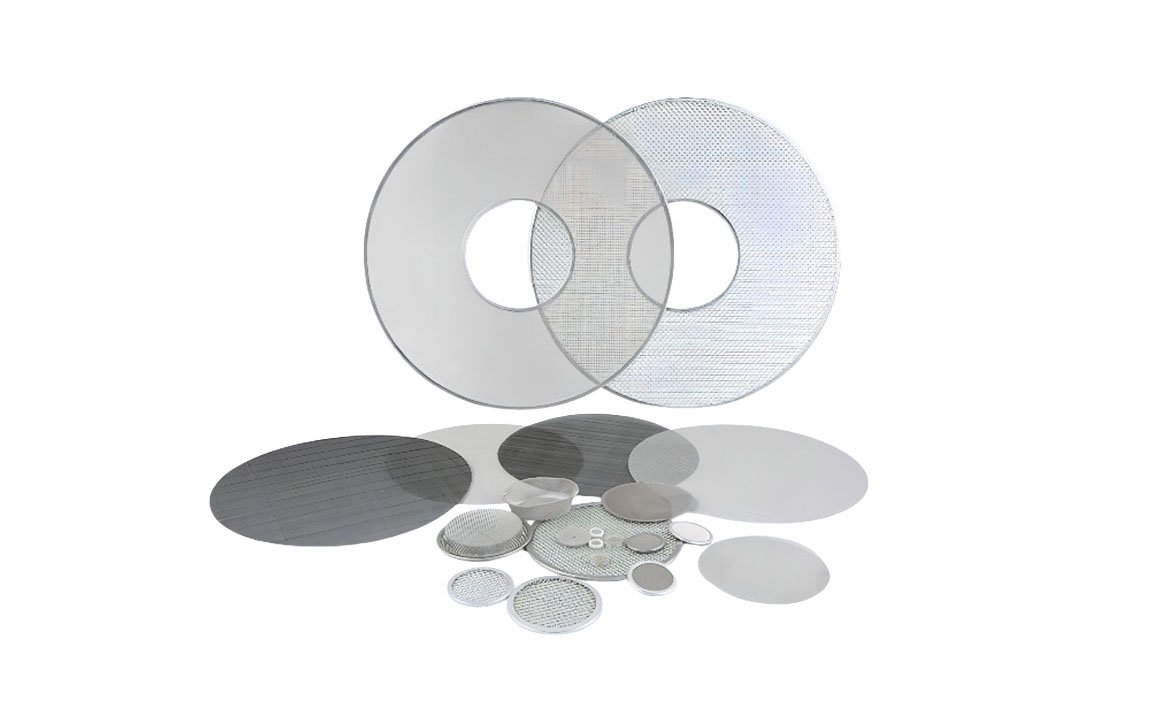

Automotive Stamping Parts Optical Sorting Solution

The 800mm Glass Turntable Optical Sorting Machineutilizes its large disc to inspect flat automotive brackets and shims for burrs and flatness deviations. Its 12-camera setup covers the entire profile, ensuring these structural components fit perfectly during vehicle assembly.

Automotive Rubber and Sealing Components Optical Sorting Solution

The glass table allows for non-contact inspection of oil seals and gaskets, preventing deformation during the testing process. The system effectively detects flash and flow marks on both the sealing lip and outer diameter, ensuring leak-free performance in engine applications.

Automotive Fasteners Optical Sorting Solution

Designed for critical fasteners like flange nuts and lock washers, the system measures thread pitch and inner diameters to ±0.002mm. Multi-view cameras simultaneously check for plating peeling and heat-treatment discoloration, preventing defective fasteners from entering the supply chain.

Electronics Structural Components Optical Sorting Solution

Internal structural frames and SIM card trays are rigorously inspected for bending and dimensional accuracy. The system verifies that these intricate flat parts stay within tolerance to ensure the precise alignment of internal components in smart devices.

Electronics Micro-precision Parts Optical Sorting Solution

Utilizing high-magnification lenses, the system sorts micro-screws and contacts to identify microscopic burrs or deformation. This ensures robust electrical performance in miniaturized devices by detecting micron-level defects on tiny connectivity parts.

Electronics Metal Hardware Optical Sorting Solution

For aesthetic metal parts like laptop hinges and camera rings, the 800mm Glass Turntable Optical Sorting Machinedetects minute surface scratches and anodizing defects. Comprehensive camera coverage ensures that side-walls and chamfered edges meet the strict cosmetic standards of high-end consumer electronics.

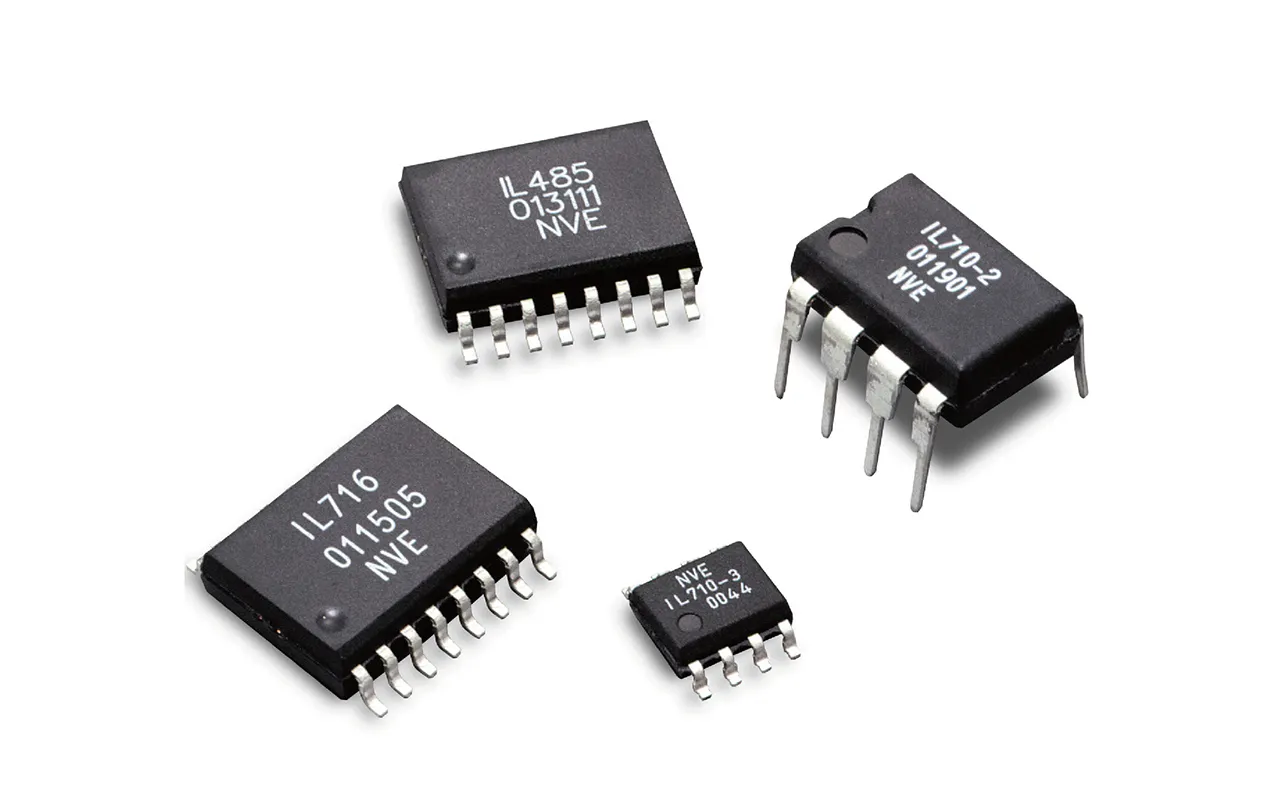

Semiconductor Passive Components Optical Sorting Solution

Large batches of chip resistors and capacitors are sorted for dimensional uniformity and termination quality. High throughput capabilities help manufacturers maintain yield rates while filtering out components with electrode defects.

Semiconductor Packaged Devices Optical Sorting Solution

The machine inspects semiconductor devices and heat spreaders for lead coplanarity, utilizing advanced lighting to detect micro-cracks and marking defects. This ensures that only structurally sound packages proceed to final assembly, minimizing the risk of device failure.

Medical Injection Molding Consumables Optical Sorting Solution

The system ensures the safety of medical consumables like vial caps and syringe plungers by detecting black spots and molding defects in a clean environment. The glass platform enables non-contact inspection essential for meeting FDA and GMP compliance requirements.

Medical Electronic Components Optical Sorting Solution

The 800mm Glass Turntable Optical Sorting Machineinspects delicate connectors and sensors used in diagnostic equipment for pin alignment and surface oxidation. Its high-precision dimensional checks guarantee the reliability of electronic interfaces in life-saving medical devices.

Military Precision Fasteners Optical Sorting Solution

For mission-critical applications, the 800mm Glass Turntable Optical Sorting Machineprovides 100% inspection of specialized locknuts and washers. It verifies thread integrity, surface finish, and dimensional tolerances to eliminate failure risks in high-stress military environments.

Ammunition Components Optical Sorting Solution

The system inspects flat ammunition components such as casing bases and primer cups for indentations, scratches, and manufacturing inconsistencies. Automated high-speed sorting ensures the reliability of supplies while removing human error from the critical inspection process.

Product Parameters

| Item | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

|---|---|---|---|---|

| Model | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

| Detection disc diameter | 500mm | 600mm | 800mm | 1000mm |

| Equipment size | 928*1000*1900 | 1060*1060*1900 | 1280*1280*1980 | 1280*1480*1980 |

| Equipment weight | 750KG | 800KG | 900KG | 1000KG |

| Voltage | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) |

| Frequency | 50HZ/60HZ | |||

| Power | 3KW | 4KW | ||

| Air pressure | 0.5-0.8Mpa | |||

| Applicable workpiece | Utilizing the high light transmittance of glass, workpieces that can be placed stably on the glass plate can be inspected. | |||

| Feeding method | Belt and rail conveyors | |||

| Feeding direction | clockwise/counterclockwise | |||

| Inspection items | Dimensional and appearance defects, such as diagonal edges, head size, stem, inner hole, pits, cracks, tooth damage, etc. | |||

| Maximum number of cameras | 4 Pcs | 8 Pcs | 12 Pcs | 16 Pcs |

| Speed | ±800Pcs/min | ±600Pcs/min | ±500Pcs/min | |

| Accuracy | ≥±0.002mm | |||

| Accessories can be added | It can be equipped with vertical feeding machines, climbing machines, storage bins, etc., and can be connected to packaging and baling machines. | |||

| Computer | Standard I7 industrial-grade computer (AI algorithm equipped with NVIDIA high computing power graphics card) | |||

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + AI algorithm platform UIDI + AI defect generation software UIDG. | |||

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province