Software Advantages

Comprehensive 360° Defect Detection

The UGO-EA-I employs both internal and external prism-based 360° inspection cameras combined with top/bottom appearance cameras using custom combined light sources. This multi-angle approach ensures complete surface coverage, detecting burrs, raw edges, flow marks, cracks, pitting, mold contamination, and foreign material inclusions that single-view systems miss.

AI-Accelerated Inspection Intelligence

Powered by UNITECHO's proprietary three-platform AI ecosystem—UZVISION visual platform, UIDI algorithm platform, and UIDG defect generation software—the system leverages an industrial-grade i7 computer with NVIDIA high-computing graphics card. The AI model database, built from over 3,000 industry customers and 1,000+ product types, enables rapid deployment with minimal sample training.

Precision Telecentric Measurement

Top and bottom size detection cameras utilize telecentric lenses to eliminate perspective distortion, ensuring accurate dimensional measurement across the entire 5-65mm outer diameter and 1.0-6.0mm thickness detection range. This optical configuration guarantees consistent measurement regardless of part positioning on the glass plate.

Intelligent Sorting & Data Management

The 4-port discharge system (OK port, dimension NG port, surface NG port, uncertain port) enables precise classification based on inspection results. Integrated data management automatically logs all measurements and defect images, generating comprehensive quality reports for full production traceability.

Rapid Changeover & Model Generation

UIDG defect generation software dramatically reduces setup time when switching product batches by automatically generating defect samples for AI training. This eliminates the traditional bottleneck of collecting physical defect samples, enabling faster production line transitions and reduced downtime.

User-Friendly Operation Interface

The UZVISION platform features an intuitive interface that simplifies recipe creation and parameter adjustment. Operators can quickly configure inspection criteria without extensive programming knowledge, while the system's pattern recognition automatically adapts to part orientation variations.

Usage Scenarios

Automotive Rubber & Sealing Components

The UGO-FA-II with slope climbing machine feeding provides efficient automated inspection of O-rings, flat gaskets, rectangular rings, bearing seals, and oil seals for automotive production lines. The 11-camera system accurately detects burrs, raw edges, flow marks, cracks, pitting, mold dirt, and material deficiencies critical to seal performance in engine, transmission, braking, and hydraulic system applications.

Automotive Plastic Parts & Structural Components

The UGO-FA-II effectively inspects small rubber-plastic composite sealing components and plastic gaskets used in automotive assemblies. The system detects surface defects, including flow marks, lack of material, sticky skin, and dimensional variations, to ensure assembly fit and sealing integrity for interior and exterior automotive applications.

Electronics Plastic Parts

The UGO-FB-II inspects precision waterproof gaskets, environmental seals, and camera module O-rings for high-volume smartphone and tablet production at maximum speeds. The dual 800mm platform with 24-camera coverage verifies IP67/IP68 waterproof integrity by detecting flow marks, shrinkage voids, and cosmetic defects.

Electronics Micro-precision Parts

The system inspects micro-O-rings and ultra-small silicone seals (down to 5mm OD) for wireless earbuds, smartwatches, and AR/VR devices with high-magnification telecentric optics across 24 cameras. The dual 800mm platform architecture delivers maximum throughput capacity while maintaining ±0.01mm dimensional accuracy for automated micro-assembly operations.

Medical Injection Molding Consumables

The flagship dual 800mm system provides maximum-throughput sterile inspection of pharmaceutical-grade rubber stoppers, syringe plungers, infusion set gaskets, and vial seals for large-scale pharmaceutical manufacturing. The 24-camera AI system ensures compliance with FDA 21 CFR Part 211, ISO 13485, and EU MDR standards by detecting contamination particles, dimensional deviations, and material defects.

Military Precision Fasteners

The machine verifies Mil-Spec tolerances on aviation screws, specifically checking head dimensions and lengths to ensure absolute airworthiness.

Military Optoelectronic Components

It performs non-contact dimensional inspection on sensitive lenses and filters, preserving flawless optical performance without risk of damage.

Military Special Material Components

The system guarantees the structural consistency and dimensional accuracy of tungsten and ceramic parts designed for extreme thermal and kinetic environments.

Product Parameters

| Category | Item | UGO-E-I | UGO-F-I-II | UGO-F-I-III |

|---|---|---|---|---|

| Equipment Parameter | Model | UGO-E-I | UGO-F-I-II | UGO-F-I-III |

| Detection disc diameter | 600mm | 800mm | ||

| Equipment size | 1080*1080*2210 | 1100*1100*2110 | 1330*1330*2280 | |

| Equipment weight | 700KG | 720KG | 850KG | |

| Voltage | 220VAC (Standard) | 220VAC (Standard) | 220VAC (Standard) | |

| Frequency | 50HZ/60HZ | 50HZ/60HZ | 50HZ/60HZ | |

| Power | 3KW | 3KW | 3KW | |

| Air pressure | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | |

| Technical Characteristic | Applicable workpiece | O-rings, flat gaskets, rectangular rings, bearing seals, oil seals and other rubber products. | Same as left | Same as left |

| Detection appearance items | Burr, flash, flow mark, lack of material, stuck material, deformation, fracture, wear, dirty, impurities, etc. | Same as left | Same as left | |

| Detection size range | Outer diameter 5-65mm, thickness 1.0mm-6.0mm | Same as left | Same as left | |

| Feeding method | Vibrating plate feeding | Slope climbing machine feeding | Vibrating plate feeding | |

| Maximum number of cameras | 10 Pcs | 11 Pcs | 16 Pcs | |

| Speed | 120-1000pcs/min (Depending on product specifications or number of cameras) | Same as left | Same as left | |

| Accuracy | Repeatability ±0.01mm | Same as left | Same as left | |

| Discharge opening | 4 discharge ports (OK port, dimension NG port, plane NG port, uncertain port) | Same as left | Same as left | |

| Peripheral facilities | Vertical loading machine, packaging machine | Packaging machine | Vertical loading machine, packaging machine | |

| Computer | Standard industrial-grade computer (AI algorithm equipped with NVIDIA high-computing power graphics card) | Same as left | Same as left | |

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + Algorithm platform UIDI + AI detect generation software UDG. | Same as left | Same as left |

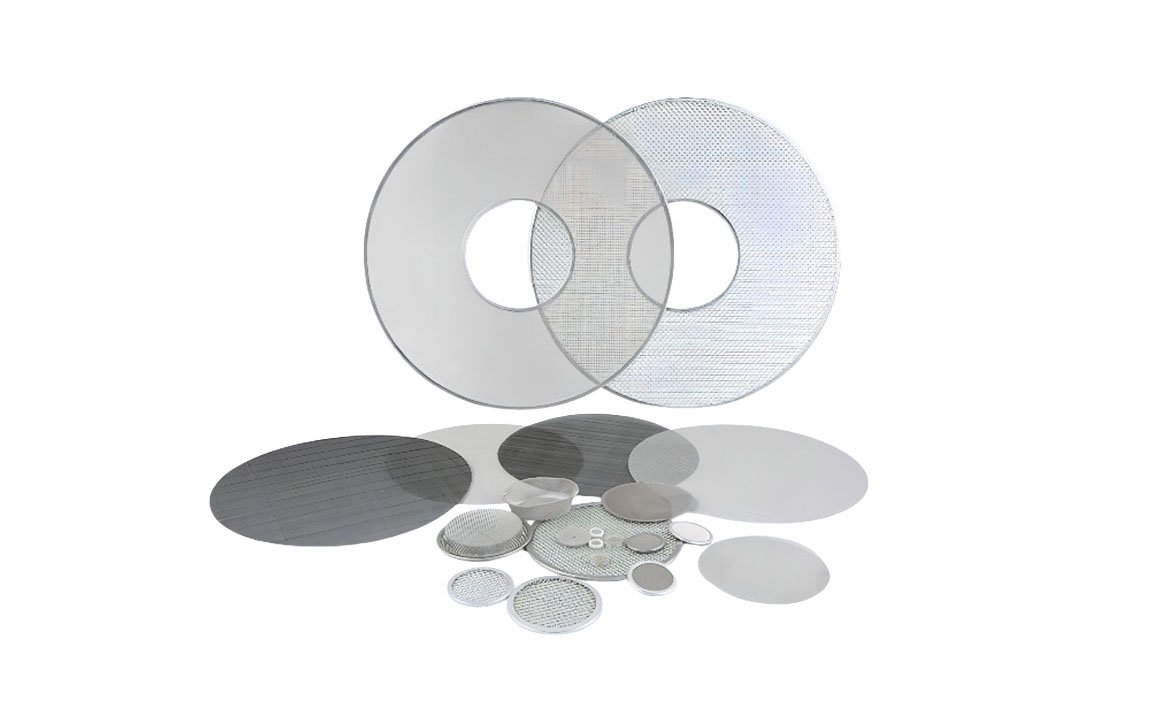

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province