UGV-D-VI Glass Turntable Metal Parts Optical Sorting Machine

The UGV-D-VI is a high-efficiency glass turntable sorting machine designed for the rapid inspection of flat, stable workpieces. Featuring a 500mm high-transparency glass disc and a 4-camera optical system, it offers the highest throughput in its series, reaching speeds of ±800 pcs/min. With a precision of ≥ ±0.002mm, this compact unit utilizes UNITECHO’s AI ecosystem to detect dimensional and surface defects on nuts, stamping parts, and electronic hardware, ensuring zero-defect output for high-volume production lines.

✅ 500mm Glass Turntable for Stable, Vibration-Free Inspection

✅ Ultra-High Speed: Up to ±800 pcs/min for Maximum Throughput

✅ 4-Camera System for Top, Bottom, and Side Defect Analysis

✅ AI-Powered UZVISION Platform with UIDG Defect Generation Software

Software Advantages

Advanced Multi-Camera Array

The Glass Turntable Optical Sorting Machine features a 4 to 16 camera array for versatile inspections. It uses the glass plate's high light transmittance to perform comprehensive inspections, eliminating blind spots and ensuring reliable defect detection on various components.

Micron-Level Dimensional Accuracy

This machine ensures precision with ±0.002mm repeatability accuracy, automatically measuring critical dimensions. It replaces manual gauging, providing detailed quantitative data for each part.

Rapid Model Switching

UIDG software enables quick setup for new inspection recipes, addressing the "cold start" issue. This minimizes downtime during product changeovers.

Flexible Feeding and Integration

The machine supports various feeding methods for easy production line integration. It can connect to different machines, creating a fully automated end-of-line solution.

Robust Data Traceability

It records detailed defect data for rejected parts, facilitating SPC analysis. This helps manufacturers identify and address production issues in real-time.

Usage Scenarios

Automotive Stamping Parts Optical Sorting Solution

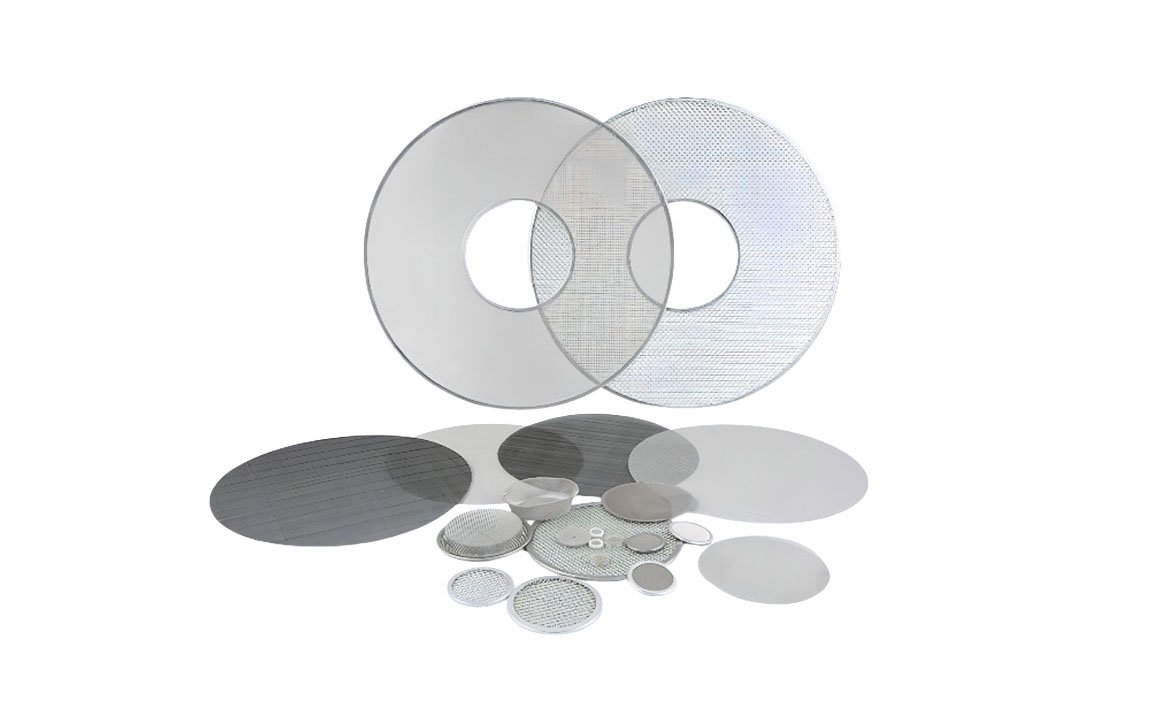

Flat automotive clips and shims are inspected on the glass table for flatness, profile distortion, and burrs using a specialized bottom-light setup. This instantly detects missing tabs or stamping die marks that exceed tolerance limits, ensuring only perfect parts reach the assembly line.

Automotive Rubber and Sealing Components Optical Sorting Solution

The friction-free glass surface is perfect for inspecting rigid rubber seals and gaskets for flash, flow marks, and mold contamination. This ensures the integrity of components used in critical engine and braking systems where leak prevention is paramount.

Automotive Precision Machined Parts Optical Sorting Solution

Precision bushings and valve seats undergo comprehensive 360° inspection on the glass disc to verify surface finish and geometric tolerances. The multi-camera system detects chatter marks and tool damage, ensuring flawless performance in transmission and steering assemblies.

Automotive Fasteners Optical Sorting Solution

The UGV-GR-VI is ideal for sorting automotive nuts and washers with ±0.002mm accuracy, ensuring strict adherence to safety standards. It precisely verifies critical thread dimensions and head heights to prevent assembly line stoppages caused by mixed or oversized parts.

Electronics Structural Components Optical Sorting Solution

Leveraging Instant One-Key Measuring technology, the system verifies complex geometric tolerances—including flatness, hole positions, and profile contours—on smartphone mid-frames and SIM trays for slim, high-density devices.

Electronics Micro-precision Parts Optical Sorting Solution

It precisely measures dimensional deviations in shielding cans and small flat hardware to ensure strict adherence to functional standards.

Electronics Metal Hardware Optical Sorting Solution

It precisely measures dimensional deviations in shielding cans and small flat hardware to ensure strict adherence to functional standards.

3C Electronics Plastic Parts Optical Sorting Solution

Leveraging Instant One-Key Measuring technology, the system verifies complex geometric tolerances—including flatness, hole positions, and profile contours—on smartphone mid-frames and SIM trays for slim, high-density devices.

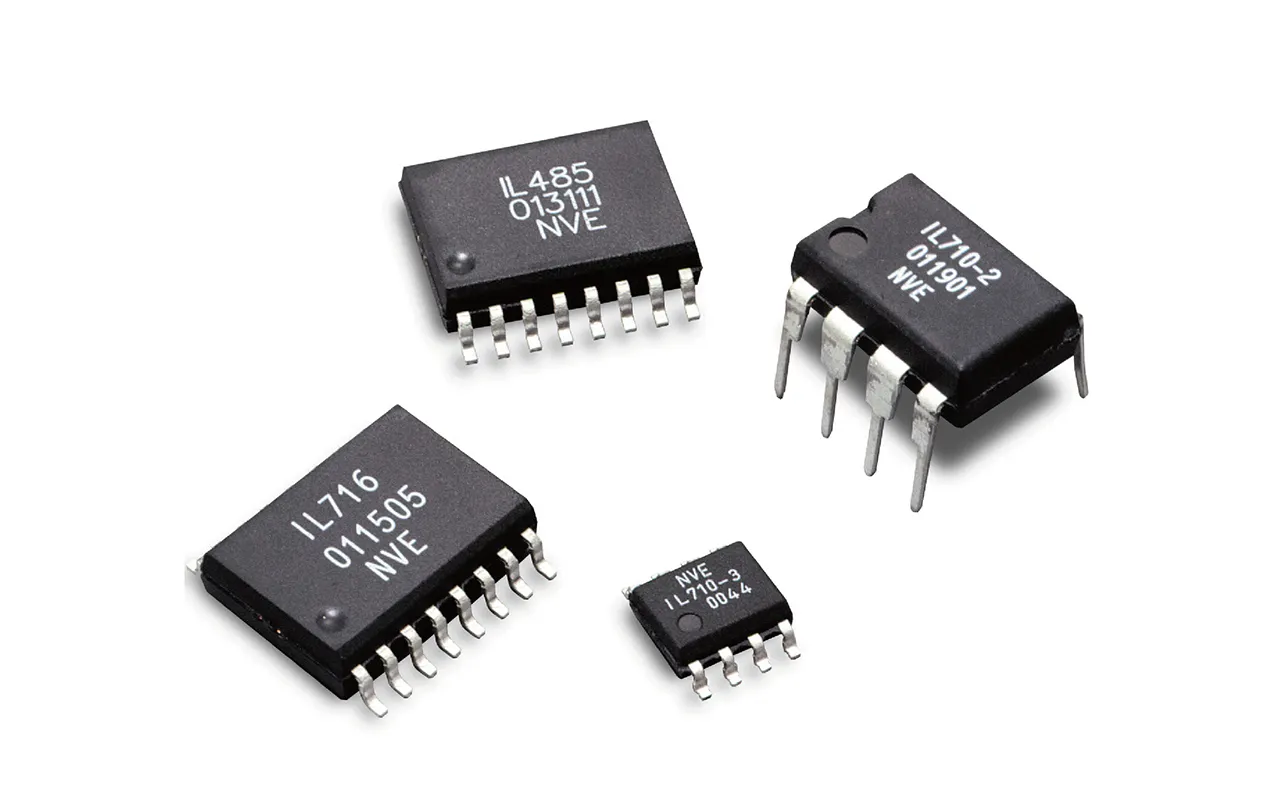

Semiconductor Passive Components Optical Sorting Solution

The series inspects the external dimensions and termination quality of passive components, detecting chips, cracks, and electrode defects. This ensures that only structurally sound components proceed to tape-and-reel packaging for final delivery.

Semiconductor Packaged Devices Optical Sorting Solution

IC packages and heat spreaders are inspected for flatness and marking legibility to prevent device failure during board mounting. High-resolution imaging identifies minute package cracks or delamination risks, ensuring high yield rates.

Medical Injection Molding Consumables Optical Sorting Solution

The glass plate system ensures the sterility of syringe plungers and vial caps by eliminating human contact during inspection. It detects black spots and molding flash, ensuring compliance with strict pharmaceutical hygiene and safety regulations.

Medical Electronic Components Optical Sorting Solution

Electrical contacts and connectors used in medical devices are inspected for plating quality and dimensional accuracy to ensure reliability. The system guarantees that critical components in diagnostic equipment are free from oxidation or deformation.

Military Precision Fasteners Optical Sorting Solution

For aerospace and defense, the system provides 100% inspection of high-strength lock nuts and washers to verify thread integrity and surface coatings. This rigorous screening prevents catastrophic failures in the high-vibration environments typical of military vehicles.

Ammunition Components Optical Sorting Solution

The machine inspects flat ammunition components like primers for indentations, scratches, and dimensional uniformity. High-speed sorting capabilities ensure the reliability and safety of small-caliber components in mass production environments.

Product Parameters

| Item | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

|---|---|---|---|---|

| Model | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

| Detection disc diameter | 500mm | 600mm | 800mm | 1000mm |

| Equipment size | 928*1000*1900 | 1060*1060*1900 | 1280*1280*1980 | 1280*1480*1980 |

| Equipment weight | 750KG | 800KG | 900KG | 1000KG |

| Voltage | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) |

| Frequency | 50HZ/60HZ | |||

| Power | 3KW | 4KW | ||

| Air pressure | 0.5-0.8Mpa | |||

| Applicable workpiece | Utilizing the high light transmittance of glass, workpieces that can be placed stably on the glass plate can be inspected. | |||

| Feeding method | Belt and rail conveyors | |||

| Feeding direction | clockwise/counterclockwise | |||

| Inspection items | Dimensional and appearance defects, such as diagonal edges, head size, stem, inner hole, pits, cracks, tooth damage, etc. | |||

| Maximum number of cameras | 4 Pcs | 8 Pcs | 12 Pcs | 16 Pcs |

| Speed | ±800Pcs/min | ±600Pcs/min | ±500Pcs/min | |

| Accuracy | ≥±0.002mm | |||

| Accessories can be added | It can be equipped with vertical feeding machines, climbing machines, storage bins, etc., and can be connected to packaging and baling machines. | |||

| Computer | Standard I7 industrial-grade computer (AI algorithm equipped with NVIDIA high computing power graphics card) | |||

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + AI algorithm platform UIDI + AI defect generation software UIDG. | |||

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province