Glass Turntable Optical Sorting Machine

- Home /

- Optical Sorting Machine /

- Glass Turntable Optical Sorting Machine

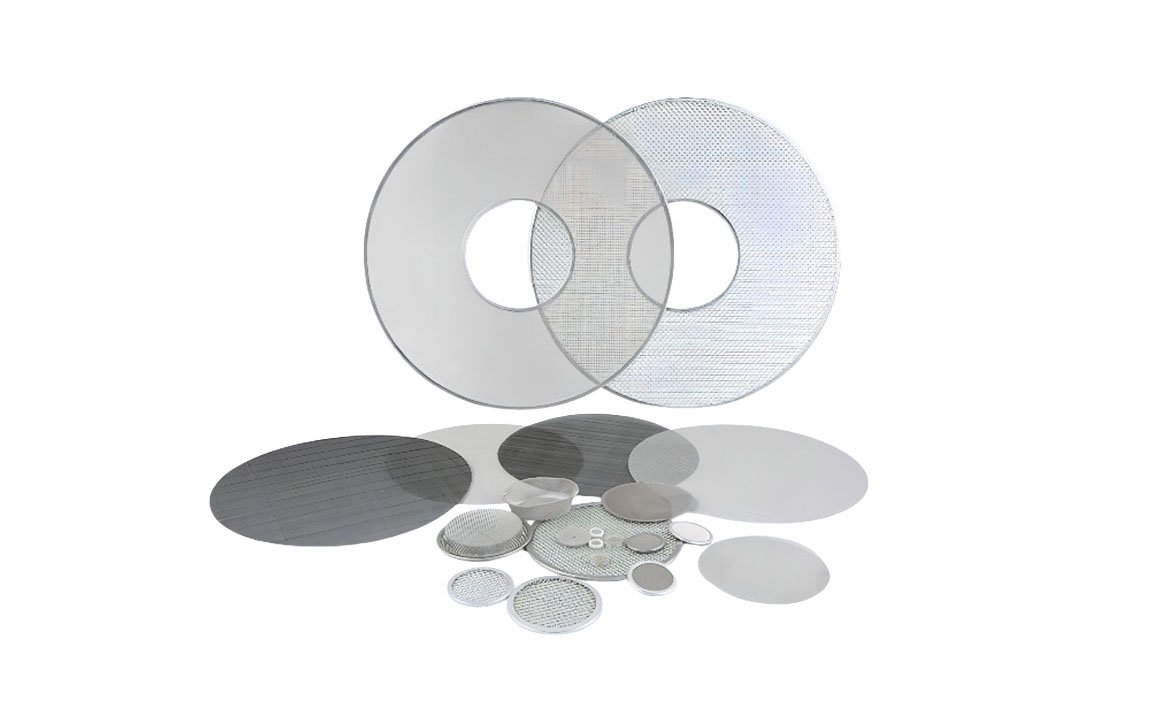

UNITECHO’s Glass Turntable Series is engineered for the high-precision inspection of stable, flat workpieces like O-rings, nuts, and washers. Utilizing high-transparency glass platforms and AI-driven multi-camera arrays, these systems deliver 360° defect detection with ≥ ±0.002mm accuracy, ensuring zero-defect automated quality control for mass production environments.

Product Series

High-Capacity 16-Camera Inspection System for Stable Industrial Components

The UNITECHO UGV-GR-VI is the largest and most capable model in the glass turntable series, featuring a massive 1000mm detection disc. Designed for high-volume manufacturing, this system is engineered to inspect workpieces that can be placed stably on a flat surface, such as nuts, washers, stamping parts, and rubber seals. With support for up to 16 high-resolution cameras, a heavy-duty 4KW drive system, and inspection speeds of ±500 pcs/min, the UGV-GR-VI offers unmatched coverage and throughput. Powered by UNITECHO’s self-developed AI ecosystem (UZVISION, UIDI, UIDG), it delivers micron-level accuracy (≥ ±0.002mm) while eliminating blind spots on large or complex flat components.

✅ Massive 1000mm Glass Detection Disc for Large Part Capacity

✅ 16-Camera Architecture for Complete 360° & Top/Bottom Inspection

✅ Heavy-Duty 4KW Power System for High-Stability Rotation

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

High-Capacity 12-Camera Visual Inspection System

The UGV-FR-VI is a robust, large-format optical sorting machine designed for the comprehensive inspection of medium-to-large flat components. Featuring an expanded 800mm high-transmittance glass detection disc, this system supports a powerful configuration of up to 12 industrial cameras. This extensive multi-view capability allows for simultaneous top, bottom, side, and angled inspections, eliminating blind spots on complex workpieces. With a measurement accuracy of ±0.002mm and a sorting speed of ≤500 pcs/min, the UGV-FR-VI delivers uncompromising quality control for automotive stampings, electronic hardware, and precision fasteners.

✅ 800mm Large-Format Glass Platform for Increased Versatility

✅ 12-Camera Matrix for 360° Blind-Spot-Free Inspection

✅ Ultra-High Precision: ±0.002mm Repeatability

✅ AI-Core: UZVISION Platform with Deep Learning Defect Detection

Ultra-Precision ±0.002mm Visual Inspection System

The UGV-ER-VI Glass Turntable Optical Sorting Machine is a versatile, high-precision optical sorting machine designed for components that require stable, flat placement inspection. Built around a 600mm high-transmittance glass detection disc, this system accommodates up to 8 industrial cameras to perform simultaneous multi-angle inspections (top, bottom, and side). With a robust inspection speed of up to 600 pcs/min and industry-leading measurement accuracy of ±0.002mm, the 600mm Glass Turntable Optical Sorting Machine is the ideal solution for manufacturers demanding zero-defect quality control for nuts, washers, stamped parts, and electronic components.

✅ 600mm High-Transmittance Glass Platform for Stable Inspection

✅ 8-Camera Configuration for Comprehensive Dimensional & Surface Analysis

✅ Micron-Level Precision: ±0.002mm Accuracy for Critical Tolerances

✅ Powered by NVIDIA GPU & UZVISION AI Deep Learning Algorithms

The UGV-D-VI is a high-efficiency glass turntable sorting machine designed for the rapid inspection of flat, stable workpieces. Featuring a 500mm high-transparency glass disc and a 4-camera optical system, it offers the highest throughput in its series, reaching speeds of ±800 pcs/min. With a precision of ≥ ±0.002mm, this compact unit utilizes UNITECHO’s AI ecosystem to detect dimensional and surface defects on nuts, stamping parts, and electronic hardware, ensuring zero-defect output for high-volume production lines.

✅ 500mm Glass Turntable for Stable, Vibration-Free Inspection

✅ Ultra-High Speed: Up to ±800 pcs/min for Maximum Throughput

✅ 4-Camera System for Top, Bottom, and Side Defect Analysis

✅ AI-Powered UZVISION Platform with UIDG Defect Generation Software

Product Comparison

Product Classification Advantages

Dual-Architecture Inspection Capability

We provide optimized handling for every geometry: our Index Plate series uses rail conveyors to securely hang top-heavy fasteners for vibration-free thread inspection, while our Glass Turntable series utilizes flat belt feeding for comprehensive top/bottom analysis of rubber and stamped parts.

Proprietary AI Ecosystem & "Cold Start" Solution

UNITECHO sets the industry standard with its self-developed UIDG software, which automatically generates virtual defect samples to train the AI. This eliminates the need for thousands of physical "bad parts," allowing manufacturers to launch new inspection models rapidly without extensive data collection.

Comprehensive Multi-View Camera Arrays

Our systems support industry-leading camera configurations—up to 12 cameras on Index models and 16 cameras on Glass models. This creates a true 360-degree view that eliminates blind spots, enabling the detection of internal "blocked holes," side cracks, and complex geometric deviations that standard systems miss.

Massive Industrial Data Intelligence

Powered by an industrial i7 computer with NVIDIA high-computing graphics, our AI algorithms are trained on a database derived from over 3,000 customers and 1,000+ product types. This pre-trained intelligence allows the system to instantly distinguish between critical functional defects and non-critical cosmetic variations.

High-Torque Stability & Precision

Featuring heavy-duty drive systems (up to 4KW) and large detection discs (up to 1000mm), our machines maintain exceptional stability even under high-load conditions. This robust engineering ensures consistent repeatability of ≥ ±0.002mm at production speeds ranging from 250 to 1000 pieces per minute.

Seamless Smart Factory Integration

All UNITECHO sorters are designed for full automation connectivity, supporting direct integration with vertical feeders, climbing conveyors, and automatic packaging/baling machines. Comprehensive data logging provides full traceability, helping manufacturers optimize upstream processes based on real-time quality analytics.

Industry Applications

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources