Index Plate Optical Sorting Machine

- Home /

- Optical Sorting Machine /

- Index Plate Optical Sorting Machine

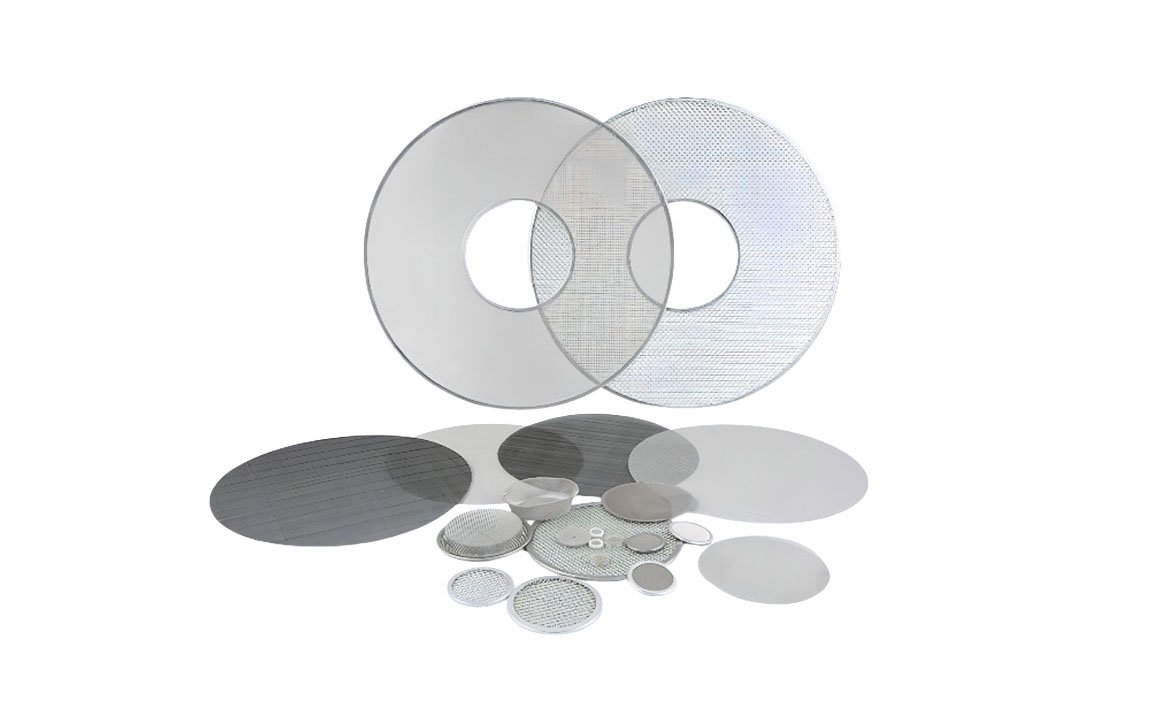

The UNITECHO UFC/UFP Index Plate Series is a specialized line of optical sorting machines engineered specifically for the inspection of “non-standing” or “headless” workpieces such as screws, bolts, rivets, and precision shafts. Unlike flat glass tables, this series utilizes a high-stability rail conveyor feeding system (track-based) to suspend parts by their heads, ensuring vertical alignment during high-speed rotation.

Available in detection disc diameters ranging from 285mm to 500mm, these machines are powered by high-torque motors (up to 4KW) to handle heavy industrial hardware. The series supports industry-leading configurations of up to 12 high-resolution cameras, enabling comprehensive 360-degree inspection of threads, dimensions, and internal features. With UNITECHO’s proprietary AI algorithms (UZVISION & UIDI) and NVIDIA computing power, the UFC/UFP series delivers micron-level accuracy (≥ ±0.002mm) at speeds up to 600 pieces per minute, making it the definitive solution for fastener quality control.

Product Series

The UNITECHO UFP-D-IV is a top-tier inspection system for large, complex hanging parts with a 500mm detection disc and 4KW drive. It features up to 12 high-resolution cameras for comprehensive analysis, ensuring zero blind spots. This machine offers precise inspections at ±250 pcs/min with ±0.002mm accuracy, ideal for critical aerospace and automotive applications.

✅ Massive 500mm Index Plate for Large Component Capacity

✅ 12-Camera Support for Comprehensive 360° & Internal Inspection

✅ Heavy-Duty 4KW Power System for High-Torque Stable Rotation

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

The UFP-B-IV Index Plate Optical Sorting Machine is designed for inspecting suspended components like screws and bolts. With a 4KW drive system, it ensures stable, continuous operation. Equipped with a 285mm detection disc and rail conveyor, it provides vibration-free 360° inspections at ±400 pcs/min with ±0.002mm accuracy. Utilizing UNITECHO’s AI ecosystem, it guarantees defect-free quality control for automotive, medical, and electronics.

✅ 285mm Index Plate with Rail Conveyors for Hanging Part Stability

✅ High-Performance 4KW Motor System for Heavy-Duty Operation

✅ 4-Camera Optical Array for Multi-Angle Dimension & Defect Analysis

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

As the flagship model for high-volume production, the 500mm Index Plate Optical Sorting Machine features a large 500mm disc and supports up to 12 cameras for superior coverage. Its precision rail conveyor securely suspends non-standing parts like bolts for stable rotation, achieving speeds of ±600 pcs/min with ≥ ±0.002mm accuracy. Powered by UNITECHO’s AI ecosystem, it delivers comprehensive 360° inspection for demanding automotive and military applications.

✅ Large 500mm Index Plate for High-Throughput & Larger Component Handling

✅ 12-Camera Array Capability for Complete 360° No-Blind-Spot Inspection

✅ High-Speed Processing: ±600 pcs/min with Industrial AI Acceleration

✅ Stable Rail Conveyor Feeding specifically for “Head-Hanging” Parts

High-Precision Index Inspection for Fasteners and Non-Standing Parts

The UFC-C-IV is a specialized index plate optical sorting machine designed specifically for the rigorous inspection of workpieces that cannot stand independently, such as screws, bolts, and suspended components. Built with a 300mm detection disc and a robust rail conveyor feeding system, this machine utilizes a 4-camera setup to perform comprehensive dimensional and defect analysis. With a detection speed of ±450 pcs/min and industry-leading accuracy of ≥ ±0.002mm, the UFC-C-IV is the ideal solution for manufacturers requiring zero-defect quality control for hanging automotive fasteners, medical screws, and precision hardware.

✅ 300mm Index Plate System

Optimized for Hanging/Suspended Workpieces

✅ 4-Camera Optical Array for Multi-Angle Thread and Surface Inspection

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics Card

✅ High-Precision Sorting up to ±450 pcs/min with ≥ ±0.002mm Accuracy

Product Comparison

Product Classification Advantages

Specialized Rail Conveyor for Hanging Stability

The system utilizes a precision rail conveyor design to securely hang top-heavy parts by their heads, eliminating the wobbling common with belt sorters. This ensures that long screws and stepped shafts remain perfectly vertical for accurate geometric measurement.

Comprehensive 12-Camera Multi-View Analysis

Supporting up to 12 cameras (on D-series models), the system offers redundant viewing angles for threads and internal bores. This configuration eliminates blind spots, reliably detecting complex defects like thread laps and internal blockages.

AI-Driven Defect Recognition & Generation

Powered by NVIDIA computing and UNITECHO's UIDI/UIDG software, the system auto-generates defect samples to solve AI "cold starts." It accurately distinguishes functional defects from cosmetic stains, significantly reducing setup time and false rejection rates.

High-Torque Industrial Performance

Equipped with heavy-duty 3KW to 4KW drive systems, these machines maintain consistent rotation stability even under heavy loads. This robust engineering ensures high throughput (up to 600 pcs/min) without compromising inspection repeatability.

Seamless Smart Factory Automation

Designed as a quality hub, the series connects directly with vertical feeders and automatic packaging lines. Its integrated data management system logs all defect statistics, providing full traceability for an unmanned "inspect-to-package" workflow.

Industry Applications

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources