Rivet cap optical screening machine, from the name can be known that it is relying on the optical principle to achieve the rivet cap screening and testing of professional equipment. It is mainly composed of optical imaging system, image acquisition device, intelligent analysis and processing system and corresponding mechanical transmission components.

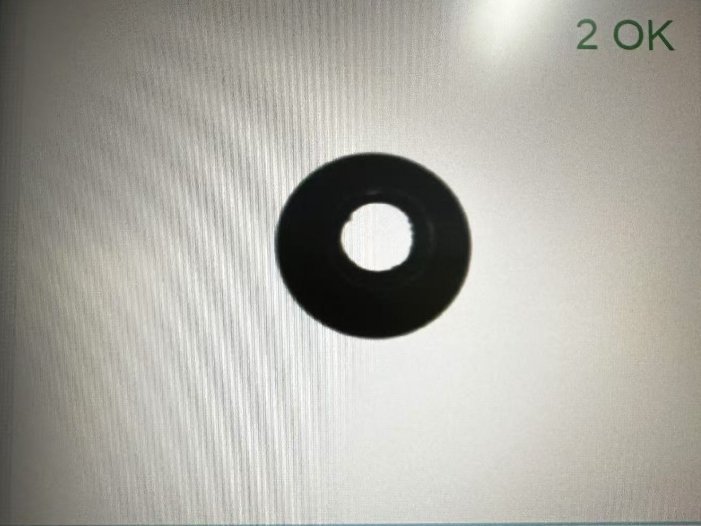

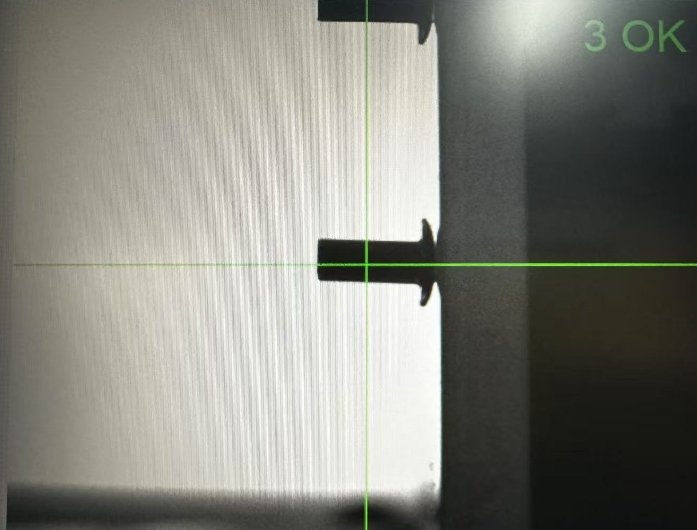

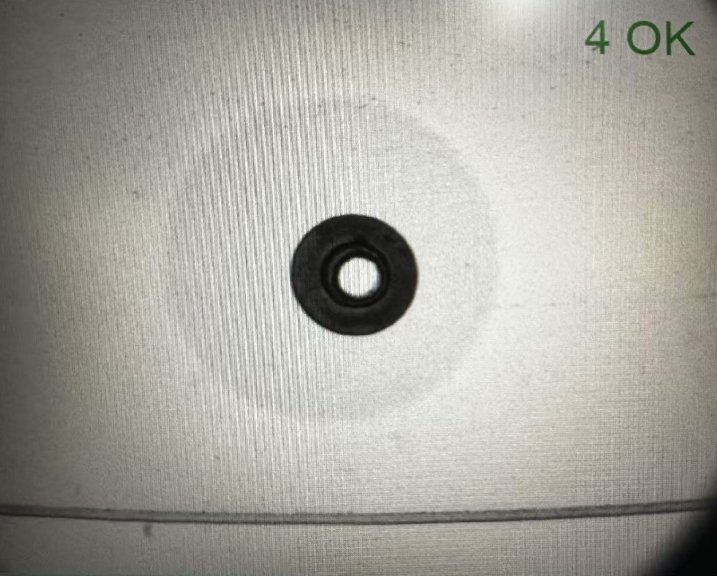

The optical imaging system is like human eyes, which can accurately capture the appearance characteristics of the riveted cap, and image every detail of the riveted cap clearly through a high-resolution lens. The image acquisition device is responsible for converting these optical images into digital signals for subsequent analysis and processing. The intelligent analysis and processing system can be said to be its “brain”, with advanced algorithms and preset standard parameters, which can quickly analyze and compare the collected image data of the riveted cap and determine whether there are dimensions deviation, surface defects, irregular shape and other quality problems. The mechanical transmission components are responsible for the orderly transport of the riveting caps, ensuring that they can enter the inspection area one by one, achieving an efficient and stable inspection process.