UGV-ER-VI Glass Turntable Metal Parts Optical Sorting Machine

Ultra-Precision ±0.002mm Visual Inspection System

The UGV-ER-VI Glass Turntable Optical Sorting Machine is a versatile, high-precision optical sorting machine designed for components that require stable, flat placement inspection. Built around a 600mm high-transmittance glass detection disc, this system accommodates up to 8 industrial cameras to perform simultaneous multi-angle inspections (top, bottom, and side). With a robust inspection speed of up to 600 pcs/min and industry-leading measurement accuracy of ±0.002mm, the 600mm Glass Turntable Optical Sorting Machine is the ideal solution for manufacturers demanding zero-defect quality control for nuts, washers, stamped parts, and electronic components.

✅ 600mm High-Transmittance Glass Platform for Stable Inspection

✅ 8-Camera Configuration for Comprehensive Dimensional & Surface Analysis

✅ Micron-Level Precision: ±0.002mm Accuracy for Critical Tolerances

✅ Powered by NVIDIA GPU & UZVISION AI Deep Learning Algorithms

Software Advantages

High-Stability Glass Plate Technology

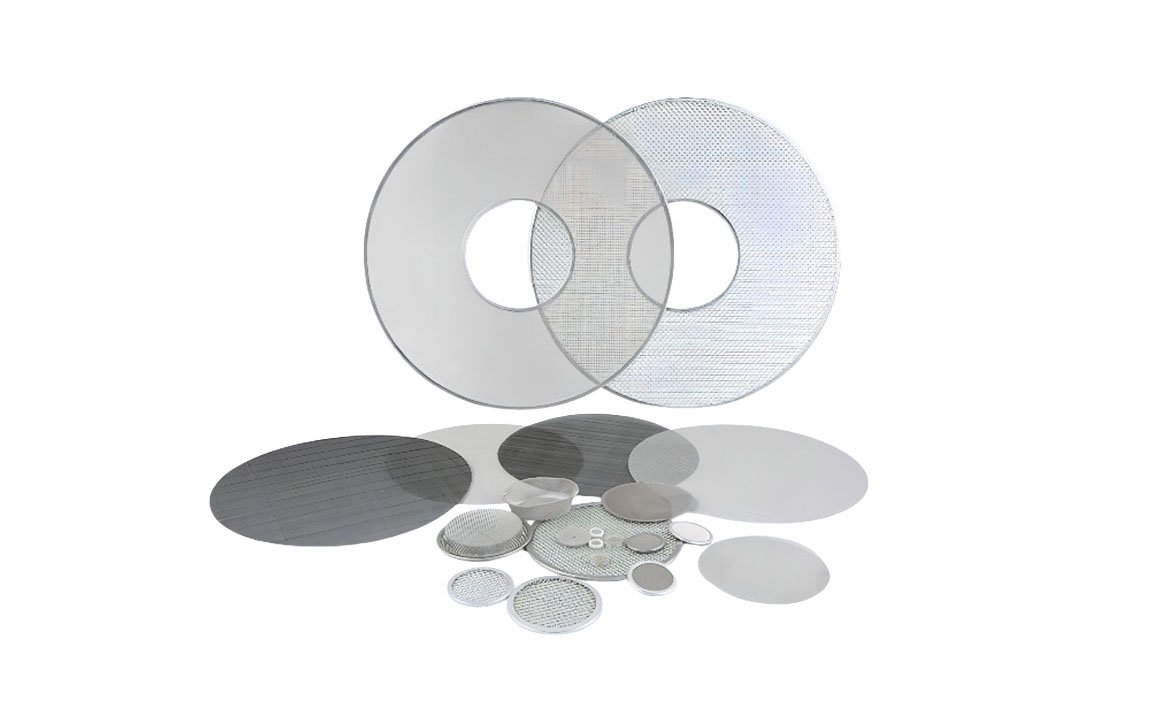

The 600mm Glass Turntable Optical Sorting Machineutilizes a specialized glass disc that allows parts to rest naturally flat for vibration-free inspection. This optical clarity enables distortion-free bottom imaging, effectively detecting internal blockages and burrs on washers and seals without the instability of other feeding methods.

AI-Driven Defect Recognition Ecosystem

Powered by UNITECHO’s proprietary software and NVIDIA high-computing GPUs, the system uses deep learning to accurately distinguish real defects from cosmetic variations. This AI ecosystem significantly improves detection rates for irregular defects like scratches and cracks that traditional rule-based algorithms often miss.

Rapid Model Setup with Defect Generation

The integrated UIDG software allows the 600mm Glass Turntable Optical Sorting Machineto autonomously generate virtual defect samples for training the AI model. This drastically reduces setup time for new products, enabling rapid deployment and recipe creation without the need for extensive physical sample collection.

Micron-Level Dimensional Control

Achieving exceptional repeatability of ±0.002mm, this system ensures critical precision for high-stakes industries like semiconductor and aerospace manufacturing. It reliably detects microscopic deviations in head size and concentricity, preventing failures where standard accuracy systems fall short.

Flexible Integration & Data Management

Designed for seamless automation, the system supports various feeding directions and integrates directly with vertical feeders and automatic packaging lines. Real-time data logging provides detailed traceability, automatically sorting parts into distinct discharge ports based on specific dimensional or appearance defects.

Usage Scenarios

Automotive Stamping Parts Optical Sorting Solution

Flat metal clips, shims, and intricate stamped components are inspected for diagonal edge defects, burrs, and missing features. The multi-camera setup verifies the profile completeness and surface flatness at speeds up to 600 parts per minute to match high-volume stamping production.

Automotive Rubber and Sealing Components Optical Sorting Solution

This system provides non-destructive inspection for oil seals, gaskets, and O-rings, utilizing the glass plate to inspect both sides without flipping the part. It effectively identifies flash, flow marks, and mold contamination that could compromise the sealing integrity of engine and transmission systems.

Automotive Precision Machined Parts Optical Sorting Solution

Small machined gears, bushings, and valve seats are inspected for tooth damage, surface pitting, and chamfer consistency. The high-resolution optics detect minute machining errors and tool marks ensuring the longevity of precision moving parts..

Automotive Fasteners Optical Sorting Solution

The UGV-ER-VI is specifically optimized for sorting automotive nuts, washers, and spacers that sit flat on the glass disc. The ±0.002mm accuracy ensures that critical thread dimensions and inner diameters strictly meet automotive safety standards, preventing assembly issues downstream.

Electronics Micro-precision Parts Optical Sorting Solution

For ultra-small components used in wearables and smartphones, the system's micron-level precision verifies tolerances that are impossible to check manually. It ensures that micro-springs, contacts, and fasteners meet the tightest geometric specifications required for miniaturized devices.

Electronics Metal Hardware Optical Sorting Solution

The machine delivers high-speed sorting for micro-nuts, standoffs, and laptop hinge components where surface finish is as important as dimension. It detects plating defects, scratches, and thread crushing to ensure the aesthetic and functional quality of premium consumer electronics.

Electronics Plastic Parts Optical Sorting Solution

Small plastic buttons, lenses, and structural frames are inspected for black spots, short shots, and flash using backlight illumination through the glass table. The AI algorithms distinguish between acceptable cosmetic variations and actual defects to maintain high yield rates.

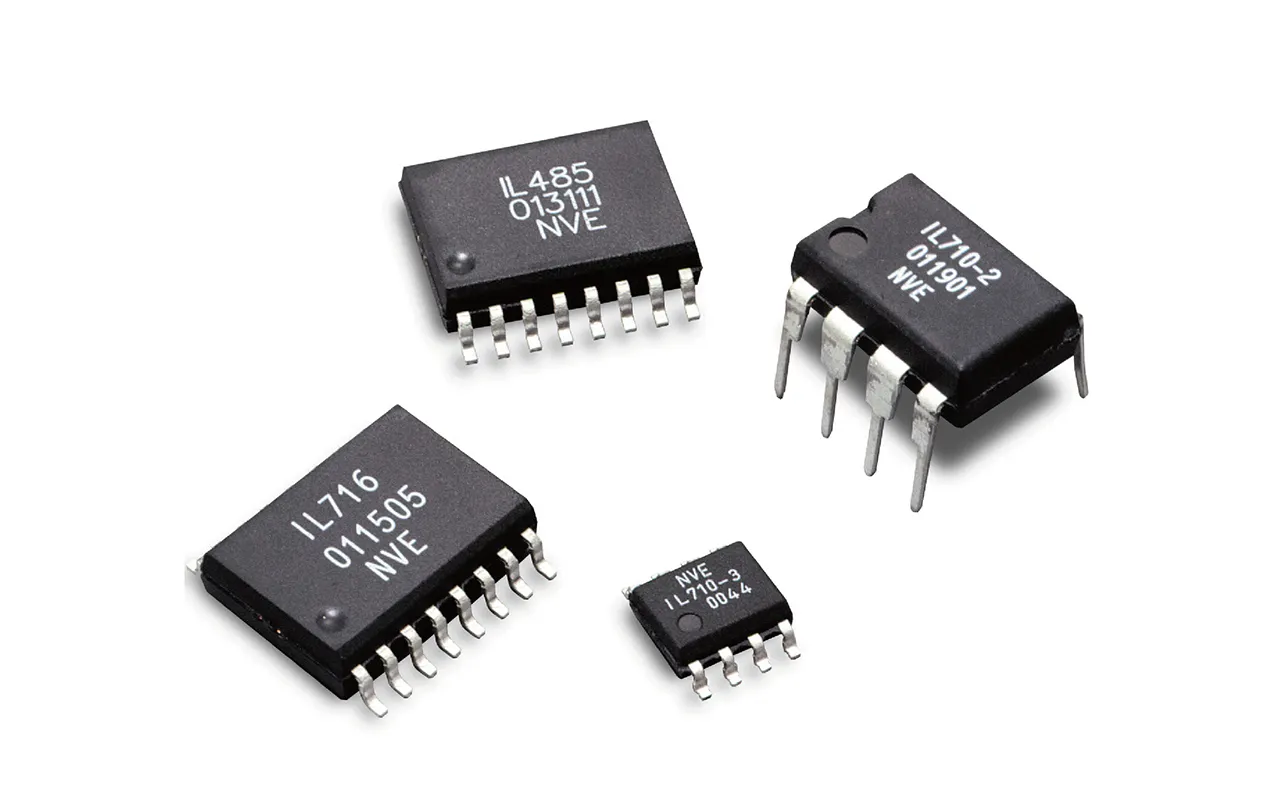

Semiconductor Passive Components Optical Sorting Solution

The UGV-ER-VI handles MLCCs, chip resistors, and inductors, checking for termination defects, cracks, and dimensional uniformity. Its high accuracy ensures that passive components meet the rigorous standards required for automated PCB assembly.

Semiconductor Packaged Devices Optical Sorting Solution

The system inspects IC packages and heat spreaders for flatness, marking legibility, and lead integrity. It identifies package cracks or delamination risks that could lead to device failure during final board mounting.

Medical Injection Molding Consumables Optical Sorting Solution

The glass plate design is ideal for the hygienic inspection of syringe plungers, rubber stoppers, and vial caps. It detects embedded foreign particles, mold flashing, and deformation, ensuring that medical consumables meet FDA standards for cleanliness and safety.

Medical Electronic Components Optical Sorting Solution

Precision contacts and connectors for medical devices are inspected for oxidation, bending, and dimensional accuracy. The system ensures high reliability for components used in life-critical monitoring and diagnostic equipment.

Military Precision Fasteners Optical Sorting Solution

Aerospace-grade lock nuts and specialized washers undergo 100% inspection to verify thread integrity and surface coating quality. The system ensures that every fastener meets the zero-failure requirements of military aviation and ground vehicle applications.

Ammunition Components Optical Sorting Solution

The machine inspects primer cups, anvils, and casing bases for indentations, scratches, and precise diameter control. The high-throughput capability ensures the safety and reliability of small-caliber ammunition components in mass defense production.

Product Parameters

| Item | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

|---|---|---|---|---|

| Model | UGV-D-VI | UGV-ER-VI | UGV-FR-VI | UGV-GR-VI |

| Detection disc diameter | 500mm | 600mm | 800mm | 1000mm |

| Equipment size | 928*1000*1900 | 1060*1060*1900 | 1280*1280*1980 | 1280*1480*1980 |

| Equipment weight | 750KG | 800KG | 900KG | 1000KG |

| Voltage | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) | 220VAC (standard) |

| Frequency | 50HZ/60HZ | |||

| Power | 3KW | 4KW | ||

| Air pressure | 0.5-0.8Mpa | |||

| Applicable workpiece | Utilizing the high light transmittance of glass, workpieces that can be placed stably on the glass plate can be inspected. | |||

| Feeding method | Belt and rail conveyors | |||

| Feeding direction | clockwise/counterclockwise | |||

| Inspection items | Dimensional and appearance defects, such as diagonal edges, head size, stem, inner hole, pits, cracks, tooth damage, etc. | |||

| Maximum number of cameras | 4 Pcs | 8 Pcs | 12 Pcs | 16 Pcs |

| Speed | ±800Pcs/min | ±600Pcs/min | ±500Pcs/min | |

| Accuracy | ≥±0.002mm | |||

| Accessories can be added | It can be equipped with vertical feeding machines, climbing machines, storage bins, etc., and can be connected to packaging and baling machines. | |||

| Computer | Standard I7 industrial-grade computer (AI algorithm equipped with NVIDIA high computing power graphics card) | |||

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + AI algorithm platform UIDI + AI defect generation software UIDG. | |||

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province