Software Advantages

Zero Negative Deviation Technology

Unlike weighing machines that estimate quantity, the MAX-VY25 uses vision to count individual items. It guarantees "No Negative Deviation", meaning customers never receive fewer parts than ordered. This significantly reduces customer complaints regarding shortages.

High-Speed CCD Imaging Algorithm

Utilizing a high-speed CCD camera and proprietary logic distribution software, the system processes 8,000 to 10,000 pieces per minute. It resolves the "unit weight error" problem common in rubber and injection molded parts, ensuring accuracy regardless of material density variations.

Rapid Changeover & Data Storage

The intelligent operating system allows for one-key switching between products. It can store data for over 1,000 different product types, making it instantly ready for use without complex recalibration.

Seamless ERP Integration

Designed for Industry 4.0, the machine supports direct connection to ERP systems. Production data, counting records, and packaging logs are fully traceable, providing complete visibility into the manufacturing process.

Usage Scenarios

Automotive Rubber & Sealing Components

The machine specifically addresses the counting challenges of O-rings and oil seals, bypassing weight fluctuations caused by temperature or batch differences to deliver unwavering accuracy.

Automotive Precision Machined Parts

It is widely used for packaging high-end precision pins and valve cores, ensuring the strict quantity control required by automotive OEMs is met consistently.

Automotive Plastic Parts & Structural Components

The system delivers accurate, high-speed packaging of plastic clips and fasteners, streamlining the production of automotive interior assembly kits.

Electronics Micro-precision Parts

The system resolves the challenge of quantifying ultra-light micro-screws (M1.0-M3.0) and tiny springs, detecting mixed parts and debris to ensure absolute kit purity for consumer electronics.

Electronics Plastic Parts

It efficiently counts small plastic buttons and optical lenses, providing a reliable alternative to weighing methods which are often affected by static electricity and weight fluctuations.

Passive Components

It serves as the ideal solution for the bulk packaging of MLCCs, resistors, and capacitors, eliminating the static damage risks associated with vibratory weighers while ensuring precise inventory control.

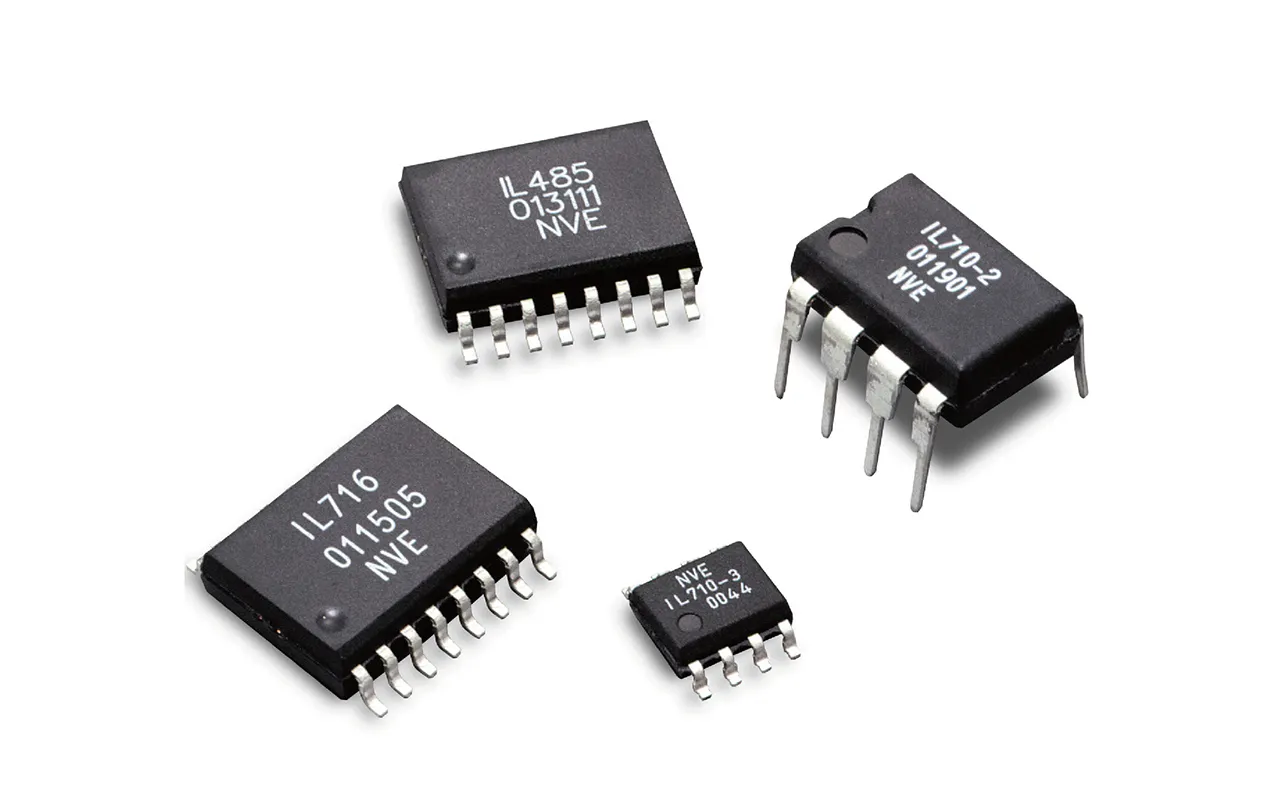

Packaged Components

The machine provides non-contact counting for IC chips and discrete devices, effectively preventing lead deformation while maintaining high throughput speeds.

Semiconductor Interconnects

It guarantees the exact count of loose pins and terminals for downstream assembly, preventing connectivity issues caused by component shortages.

Medical Fasteners & Implants

The MAX-VY25 ensures 100% quantity accuracy for high-value titanium bone nails and screws, utilizing "No Negative Deviation" technology to guarantee that surgical kits are complete and compliant with safety standards.

Medical Injection Molding Consumables

This machine accurately counts sterile rubber stoppers and syringe plungers, using advanced vision algorithms to overcome the unit weight variances inherent in rubber materials.

Medical Electronic Components

The system safely packages miniature sensors and electrodes using non-contact counting to ensure exact quantities without causing physical damage to sensitive medical devices.

Military Precision Fasteners

The machine guarantees absolute zero-error counting for aviation maintenance kits, eliminating the risks of Foreign Object Damage (FOD) and logistics discrepancies in mission-critical supply chains.

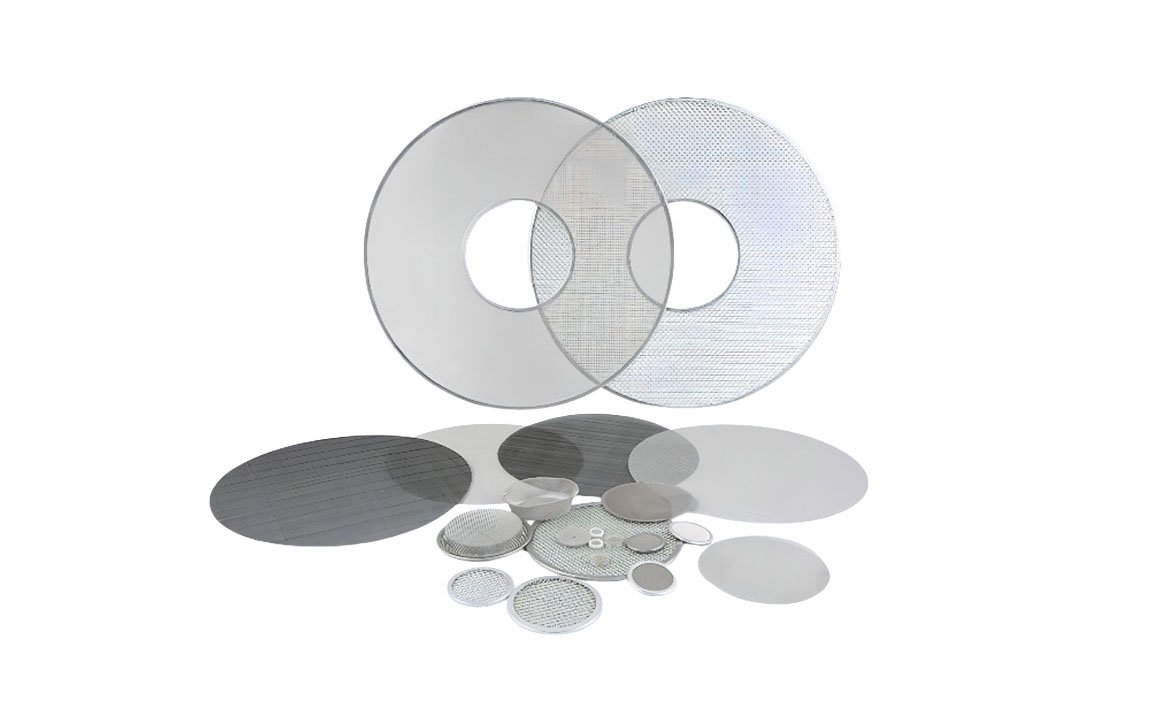

Military Optoelectronic Components

It counts sensitive optical filters and small lenses without physical contact, preserving their flawless optical performance for defense applications.

Product Parameters

| The main technical parameters | |

|---|---|

| Model | MAX-VY25 |

| Efficiency | 8000-10000pcs/min |

| Detectable size | 2mm-50mm |

| Technical precision | 0-3% No negative deviation |

| Power requirements (Voltage/Power/Frequency/Rating current) | AC220V±10%50HZ/60HZ |

| Weight | 300kg |

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province